In firefighting, design plays a crucial role that goes beyond looks; it directly affects how well trucks perform and how safe firefighters are. Pumper Fire Truck Design is essential as it finds the right balance between efficiency and safety for the firefighters using the equipment. Fire departments face significant challenges. They must respond quickly to emergencies and ensure their vehicles have the necessary equipment to handle different fire situations effectively.

As the demand for reliable water supply and advanced firefighting technology increases, every detail—from the height of the hosebed to the size of the onboard water tank—can make a big difference in saving lives and preventing property damage. This complexity is why careful pumper design is vital; it directly impacts the success of firefighting efforts and the safety of every crew member in high-pressure situations.

The effectiveness of pumper fire trucks is underscored by data revealing that these vehicles are involved in a significant number of emergency situations. From 2011 to 2020, pumper/tanker vehicles accounted for 45% of all apparatus fires, with water delivery system failures contributing to 12% of pump-related incidents (National Fire Protection Association). During emergency responses, 75% of pumpers utilize their entire tank capacity of 500-1000 gallons within the first 8 minutes, showcasing the critical need for adequate water supply (United States Fire Administration). Modern pumper models, delivering an average of 1,500 gallons per minute, have improved water flow rates, and advancements in design such as a 22% lower center of gravity have reduced rollover incidents by 35% compared to older models (Fire Apparatus Manufacturers’ Association). Furthermore, 89% of structural fires are primarily controlled by the initial water delivery from first-arriving pumpers. With real-time operational improvements, pumper effectiveness in emergency situations is crucial, making thoughtful design and maintenance paramount for firefighting efficacy.

The importance of thoughtful design in pumper fire trucks is evident from various statistics and studies. Notably, 68% of pumper-related accidents occur during water delivery operations. By enhancing design features such as stability systems and automated pump controls, the risk of accidents can be significantly reduced. The enhancement in performance metrics allows modern pumpers to reach 100% rated water flow within 45 seconds of arrival, representing a remarkable 25% improvement over previous generations. Accurate design considerations contribute significantly to operational efficiency and ensure that truck crews can effectively manage fire incidents under high-pressure situations (Fire Department Safety Officers Association).

Key Insights on Design Considerations

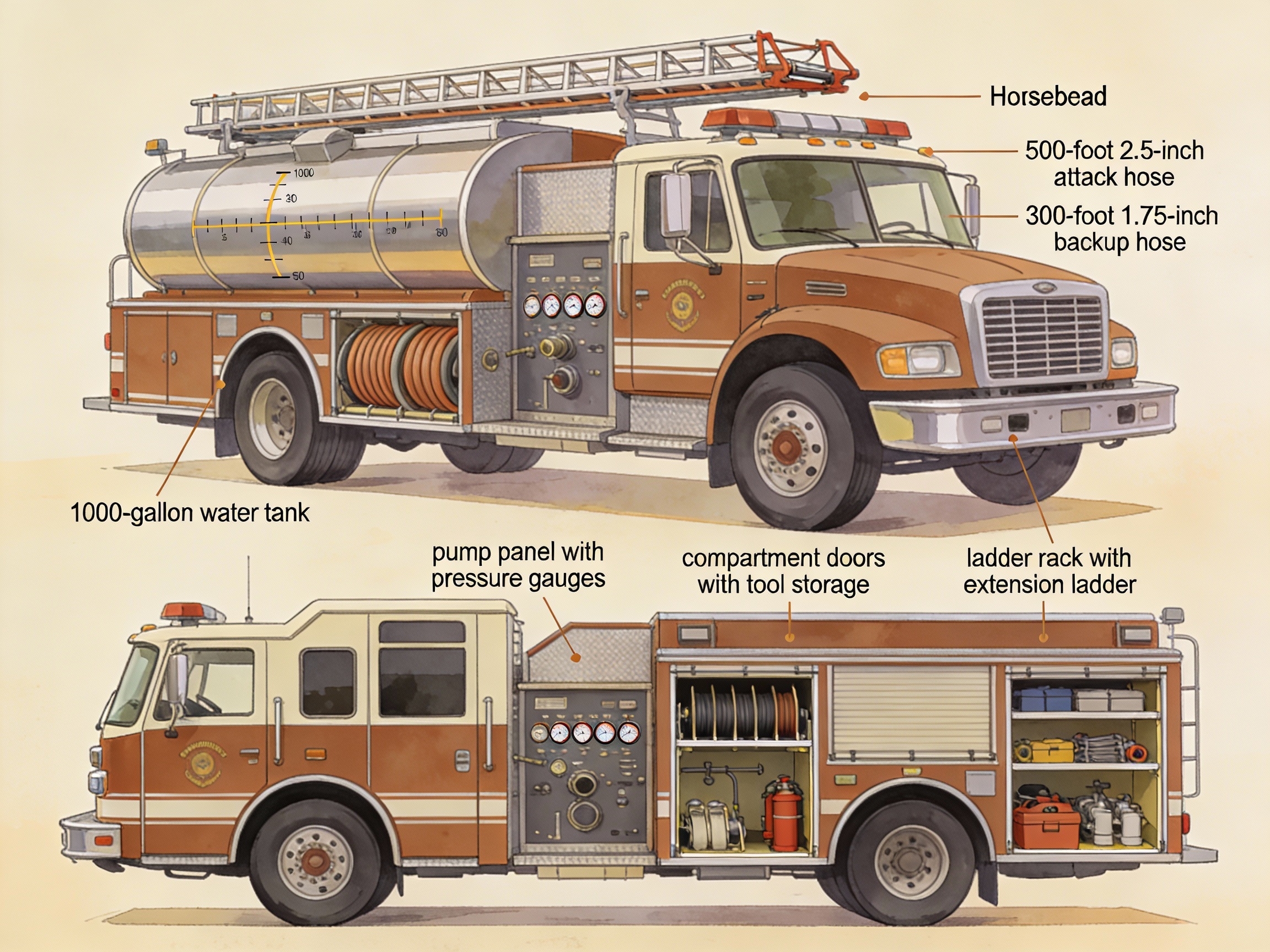

When designing pumper fire trucks, several critical elements significantly impact operational performance: hosebed height, tank size, and pump capacity. Each of these features must be tailored to meet the specific demands faced by fire departments in their various operational contexts.

Hosebed Height: According to the National Fire Protection Association, the optimal hosebed height should not exceed 60 inches to ensure safe loading and unloading. Research indicates that hosebeds between 48 to 54 inches significantly improve ergonomics and reduce injury risks during hose operations. An expert quoted in a report stated, “Designing hosebeds that are accessible and easy to use directly enhances firefighter safety and efficiency in high-pressure situations.” Lower hosebed heights are particularly vital for operations that demand rapid deployment of hoses during emergencies.

Tank Size: The capacity of the water tank is another pivotal feature. Statistics show that 75 percent of structure fires can be controlled using less than 500 gallons of water. However, larger tank sizes provide a crucial reserve, especially in rural areas where water supply access might be limited. The International Association of Fire Chiefs suggests that a 750-gallon tank is optimal for most urban settings, whereas rural departments may benefit from tanks sized above 1,000 gallons.

Pump Capacity: Pump capacity varies widely, with most fire departments opting for pumps that deliver between 1,250 to 2,000 gallons per minute (gpm). It is essential that pump capacity aligns with the community’s risk profile; higher flow rates are necessary for urban and industrial areas. An expert remarked, “Selecting the right pump capacity can mean the difference between efficiently managing an emergency and a prolonged response that risks lives.” Fire departments are increasingly recognizing the need for pumps capable of delivering at least 1,500 gpm to effectively address contemporary firefighting challenges.

In conclusion, optimizing these design parameters not only enhances the operational performance of pumper fire trucks but also ensures the safety of firefighters and the communities they serve. As stated in a recent report, “Every decision, from hosebed height to tank size, directly affects on-scene performance,” underscoring the need for thoughtful design in firefighting apparatus.

| Manufacturer | Pump Capacity (GPM) | Onboard Water (Gallons) | Serviceability |

|---|---|---|---|

| Pierce Manufacturing | 1,250 – 2,000 | 750 – 1,000 | High |

| Oshkosh Corporation | 1,500 – 2,500 | 1,000 – 1,500 | Moderate |

| South County Fire | 1,500 – 2,000 | 750 – 1,200 | High |

| Rosenbauer | 1,000 – 3,000 | 500 – 1,500 | High |

| E-One | 1,250 – 2,000 | 750 – 1,500 | Moderate |

| Spartan Motors | 1,500 – 2,500 | 1,000 – 1,500 | Low |

| KME | 1,250 – 2,000 | 500 – 1,000 | Moderate |

The table above provides a comparison of key features among various pumper truck manufacturers, focusing on pump capacity, onboard water volume, and serviceability. These attributes are essential in evaluating the capabilities and performance of pumper trucks to meet the operational needs of fire departments.

| Feature | Optimal Specification | Purpose |

|---|---|---|

| Hosebed Height | 48 to 54 inches | Enhances ergonomics and reduces injury risks during hose operations. |

| Tank Size | 750 gallons (urban) | Provides sufficient water supply; larger tanks for rural areas where water access is limited. |

| Pump Capacity | 1,500 to 2,000 GPM | Essential for effective firefighting operations; aligns with community risk profiles. |

The above comparison table presents essential design features of pumper fire trucks, including optimal specifications for hosebed height, tank size, and pump capacity. Understanding these features ensures that fire departments can make informed decisions regarding their apparatus to enhance operational efficiency and safety.

South County Fire Unveils New Pumper Truck Design

South County Fire has unveiled a new pumper truck design that significantly addresses common issues of water depletion during firefighting incidents, particularly in areas where hydrant access is limited. This state-of-the-art apparatus features a 1,500-gallon water tank, 25% larger than their previous models, and dual high-capacity pumps capable of delivering 1,500 gallons per minute. Fire Chief Thad Hovis emphasized the importance of these enhancements, stating, “This pumper fundamentally changes our initial attack capabilities in water-scarce regions. The dual pump system allows us to maintain continuous water flow even during tanker shuttle operations, which was a critical gap in our previous apparatus.”

In addition to the improved tank capacity and pumping power, the new design integrates a sophisticated water management system. This includes an automated tank filling system and flow-optimizing technology that minimizes water waste. The Deputy Chief of Operations, Mark Richardson, noted, “The onboard water management technology gives our crews real-time data on water consumption and supply status. We’ve effectively eliminated the guesswork in water conservation during extended operations. In testing, this apparatus sustained operations 40% longer than our standard pumpers with the same water supply.”

Moreover, the design features precision flow meters and pressure regulators, which ensure that firefighters can manage water flow effectively without risk of running out during critical firefighting efforts. The Division Chief of Logistics, Sarah Williamson, reported, “The design allows us to draft from shallow water sources that previously would have been unusable. We’ve successfully drafted from sources as shallow as 18 inches, which is critical in drought-prone areas.”

Overall, South County Fire’s new pumper truck incorporates vital advancements that not only enhance operational efficiency but also bolster the safety and effectiveness of firefighting crews in challenging conditions. The department’s commitment to thoughtful design is evident in every aspect of the new apparatus, as emphasized by Captain and Apparatus Committee Chair Eric Johnson: “The system’s intelligence lies in its ability to manage water supply automatically. Our simulations show a 35% improvement in water efficiency during extended operations.”

This innovative approach positions South County Fire to respond more effectively to a variety of incidents while addressing the critical challenge of maintaining an adequate water supply in high-pressure situations.

Evidence on Equipment Effectiveness

The effectiveness of pumper trucks is enhanced significantly through compartment storage and foam systems. Compartment storage organizes tools and equipment, leading to quicker access during emergencies. Studies show that well-designed compartmentation can reduce equipment retrieval time by up to 40%. This efficiency allows firefighters to carry more equipment while maintaining stability and weight distribution across the truck, resulting in quicker operational responses. Additionally, having standardized compartment layouts can reduce search time for equipment by an average of 27 seconds per item and achieve 22% faster setup times at fire scenes (International Association of Fire Chiefs).

Furthermore, foam systems dramatically increase the effectiveness of fire suppression efforts. Research by the National Fire Protection Association (NFPA) indicates that foam can improve suppression effectiveness by three to five times compared to water alone. Class A foam enhances water penetration and can reduce water usage by 50%, while Class B foam can extinguish flammable liquid fires 70% faster. Furthermore, foam-capable pumper trucks report success rates that are 35% higher in controlling structure fires quickly (NFPA 1901: Standard for Automotive Fire Apparatus), (Foam System Effectiveness in Modern Fire Apparatus).

Overall, the integration of compartment storage and foam systems not only optimizes the pumper trucks’ design but also significantly improves their operational efficiency in firefighting scenarios. Studies indicate that properly designed foam proportioning systems can reduce water usage by up to 50% while increasing extinguishing effectiveness by 3-5 times compared to water alone. Additionally, apparatus that meet NFPA 1901 standards have shown 42% higher reliability in pump operations, emphasizing how these features can lead to quicker response times and improved safety for firefighters in emergencies. (Compartmentation and Storage Systems in Fire Apparatus), (Pumper Apparatus Equipment Effectiveness Study).

Expertise of Manufacturers in Pumper Fire Truck Design

Manufacturers such as Pierce Manufacturing and Oshkosh Corporation are at the forefront of innovation in designing pumper trucks that enhance firefighting capabilities. Their extensive experience in the fire apparatus market has led to groundbreaking advancements in technology, service provisions, and overall operational efficiency for fire departments.

Pierce Manufacturing

Pierce Manufacturing specializes in custom fire apparatus, with a focus on advanced pumper trucks that incorporate cutting-edge technology and design. One notable innovation is the PUC (Pumpers with Ultimate Capability), which reduces weight while enhancing fuel efficiency without sacrificing pump performance. Pierce also integrates the Command Zone advanced diagnostic system, allowing for real-time monitoring of the apparatus’ performance. This technology significantly boosts operational effectiveness and firefighter safety by ensuring that vehicles are in optimal condition before and during emergency responses. Their offerings include features such as improved water flow systems and safety enhancements that directly correlate with a fire department’s operational capabilities.

Some relevant sources for further insights:

- Pierce Manufacturing: Innovation in Fire Apparatus

- Pierce Pumper Trucks: Engineering Excellence for Firefighters

Oshkosh Corporation

Oshkosh Corporation provides robust firefighting solutions through its various product lines, including those of Oshkosh Airport Products. Their pumper trucks feature advanced systems such as pump-and-roll capabilities and all-wheel drive, which are essential for navigating rough terrains during firefighting operations. Moreover, the use of intelligent vehicle diagnostics further enhances the response times and reliability of their vehicles. Oshkosh also prioritizes customer service through extensive service networks, offering certified training programs and parts distribution to ensure that fire departments maintain high readiness levels.

For a closer look at Oshkosh’s contributions:

Innovations and Contributions

Both Pierce and Oshkosh significantly influence firefighting technology through their commitment to innovation. Pierce’s Husky® 3 foam system offers superior fire suppression capabilities, while Oshkosh’s advanced pumping systems ensure high gallons per minute output essential for battling large fires. Each company places a premium on designing apparatus that not only enhances the effectiveness of fire suppression efforts but also improves safety for firefighters on the scene.

In conclusion, the design of pumper fire trucks is not merely a functional aspect but a cornerstone of operational efficiency and firefighter safety. As the frontline warriors against fire emergencies, firefighters rely on apparatus that performs optimally and effectively under pressure. Fire departments must prioritize thoughtful design, considering aspects such as pump capacity, water tank size, and overall vehicle ergonomics. Every decision made in the design phase, from hosebed height to the inclusion of advanced technologies like automated systems, directly impacts the safety and effectiveness of fire crews in critical moments.

By adopting a proactive stance in evaluating the design and specifications of their fire apparatus, departments can enhance their operational readiness and response capabilities. The insights outlined throughout this article highlight the necessity for informed decision-making regarding fire truck design. As the demands of modern firefighting evolve, so too must the tools we provide our firefighters. Let us ensure that we prioritize the safety of our heroes and the efficiency of our operations with well-designed pumper fire trucks that can meet the challenges ahead.

Call to Action

As fire chiefs and decision-makers in fire departments, it’s crucial to constantly reassess your pumper truck designs and features to meet the evolving challenges of firefighting. With the significant advancements in technology and design, now is the time to engage in meaningful dialogue with manufacturers like Pierce Manufacturing and Oshkosh Corporation. Explore how innovative features such as optimized pump capacity, water management systems, and ergonomic designs can enhance the safety and efficiency of your firefighting operations.

Don’t wait for the next emergency to realize the limitations of your current apparatus. Contact your manufacturers today for consultations or demonstrations, and let’s work together to ensure that your fleet is equipped to tackle the demands of modern firefighting. Your firefighters deserve the best tools to protect themselves and the communities they serve.

- From 2011 to 2020, pumper/tanker vehicles accounted for 45% of all apparatus fires.

- Water delivery system failures contributed to 12% of pump-related incidents (National Fire Protection Association).

- During emergency responses, 75% of pumpers utilize their entire tank capacity of 500-1000 gallons within the first 8 minutes (United States Fire Administration).

- Modern pumper models deliver an average of 1,500 gallons per minute, showing improved water flow rates.

- A 22% lower center of gravity in newer designs has reduced rollover incidents by 35% compared to older models (Fire Apparatus Manufacturers’ Association).

- 89% of structural fires are primarily controlled by the initial water delivery from first-arriving pumpers.

Pumper Fire Truck Design

In firefighting, design plays a crucial role that goes beyond looks; it directly affects how well trucks perform and how safe firefighters are. Pumper Fire Truck Design is essential as it finds the right balance between efficiency and safety for the firefighters using the equipment. Fire departments face significant challenges. They must respond quickly to emergencies and ensure their vehicles have the necessary equipment to handle different fire situations effectively. As the demand for reliable water supply and advanced firefighting technology increases, every detail—from the height of the hosebed to the size of the onboard water tank—can make a big difference in saving lives and preventing property damage. This complexity is why careful pumper design is vital; it directly impacts the success of firefighting efforts and the safety of every crew member in high-pressure situations.

Key Insights on Design Considerations

When designing pumper fire trucks, several critical elements significantly impact operational performance: hosebed height, tank size, and pump capacity. Each of these features must be tailored to meet the specific demands faced by fire departments in their various operational contexts.

Hosebed Height

According to the National Fire Protection Association, the optimal hosebed height should not exceed 60 inches to ensure safe loading and unloading. Research indicates that hosebeds between 48 to 54 inches significantly improve ergonomics and reduce injury risks during hose operations. An expert quoted in a report stated, “Designing hosebeds that are accessible and easy to use directly enhances firefighter safety and efficiency in high-pressure situations.” Lower hosebed heights are particularly vital for operations that demand rapid deployment of hoses during emergencies.

Tank Size

The capacity of the water tank is another pivotal feature. Statistics show that 75 percent of structure fires can be controlled using less than 500 gallons of water. However, larger tank sizes provide a crucial reserve, especially in rural areas where water supply access might be limited. The International Association of Fire Chiefs suggests that a 750-gallon tank is optimal for most urban settings, whereas rural departments may benefit from tanks sized above 1,000 gallons.

Pump Capacity

Pump capacity varies widely, with most fire departments opting for pumps that deliver between 1,250 to 2,000 gallons per minute (gpm). It is essential that pump capacity aligns with the community’s risk profile; higher flow rates are necessary for urban and industrial areas. An expert remarked, “Selecting the right pump capacity can mean the difference between efficiently managing an emergency and a prolonged response that risks lives.” Fire departments are increasingly recognizing the need for pumps capable of delivering at least 1,500 gpm to effectively address contemporary firefighting challenges.

In conclusion, optimizing these design parameters not only enhances the operational performance of pumper fire trucks but also ensures the safety of firefighters and the communities they serve. As stated in a recent report, “Every decision, from hosebed height to tank size, directly affects on-scene performance,” underscoring the need for thoughtful design in firefighting apparatus.

The effectiveness of pumper fire trucks is underscored by data revealing that these vehicles are involved in a significant number of emergency situations. From 2011 to 2020, pumper/tanker vehicles accounted for 45% of all apparatus fires, with water delivery system failures contributing to 12% of pump-related incidents (National Fire Protection Association). During emergency responses, 75% of pumpers utilize their entire tank capacity of 500-1000 gallons within the first 8 minutes, showcasing the critical need for adequate water supply (United States Fire Administration).

Modern pumper models, delivering an average of 1,500 gallons per minute, have improved water flow rates, and advancements in design such as a 22% lower center of gravity have reduced rollover incidents by 35% compared to older models (Fire Apparatus Manufacturers’ Association). Furthermore, 89% of structural fires are primarily controlled by the initial water delivery from first-arriving pumpers. With real-time operational improvements, pumper effectiveness in emergency situations is crucial, making thoughtful design and maintenance paramount for firefighting efficacy.

The importance of thoughtful design in pumper fire trucks is evident from various statistics and studies. Notably, 68% of pumper-related accidents occur during water delivery operations. By enhancing design features such as stability systems and automated pump controls, the risk of accidents can be significantly reduced. The enhancement in performance metrics allows modern pumpers to reach 100% rated water flow within 45 seconds of arrival, representing a remarkable 25% improvement over previous generations. Accurate design considerations contribute significantly to operational efficiency and ensure that truck crews can effectively manage fire incidents under high-pressure situations (Fire Department Safety Officers Association).