Rescue fire trucks represent an indispensable line of defense in today’s emergency response landscape. Unlike standard fire engines, these specialized vehicles epitomize the fusion of advanced technology and versatility, designed not just for extinguishing flames but also for performing critical rescues in time-sensitive situations. Through this exploration, the focus will be on their key features, operational importance, and technological innovations. Delving into these aspects will shed light on how rescue fire trucks save lives and enhance the capabilities of emergency responders.

Beyond the Fire Line: Inside the Rescue Fire Truck, a Lifesaving Arsenal on Wheels

A rescue fire truck is more than a larger version of a firefighting rig. It is a purpose-built response platform that expands a crew’s capabilities far beyond delivering water to a blaze. When seconds count and the scene is tangled with twisted metal, unstable structures, or hazardous substances, a rescue vehicle brings a carefully curated set of tools, systems, and organizational logic that turns time into life-saving action. Its design centers on rapid response, versatile rescue operations, and the ability to support medical care while maintaining responder safety. In practical terms, this means a truck that can arrive at diverse emergencies and immediately switch from suppression to extraction, stabilization, and patient care. The result is a vehicle that acts as a mobile workshop, a field hospital, and a command post rolled into one wheeled platform. The core idea behind a rescue truck is not simply to add gadgets, but to weave those gadgets into a coherent workflow that can adapt as the incident evolves.

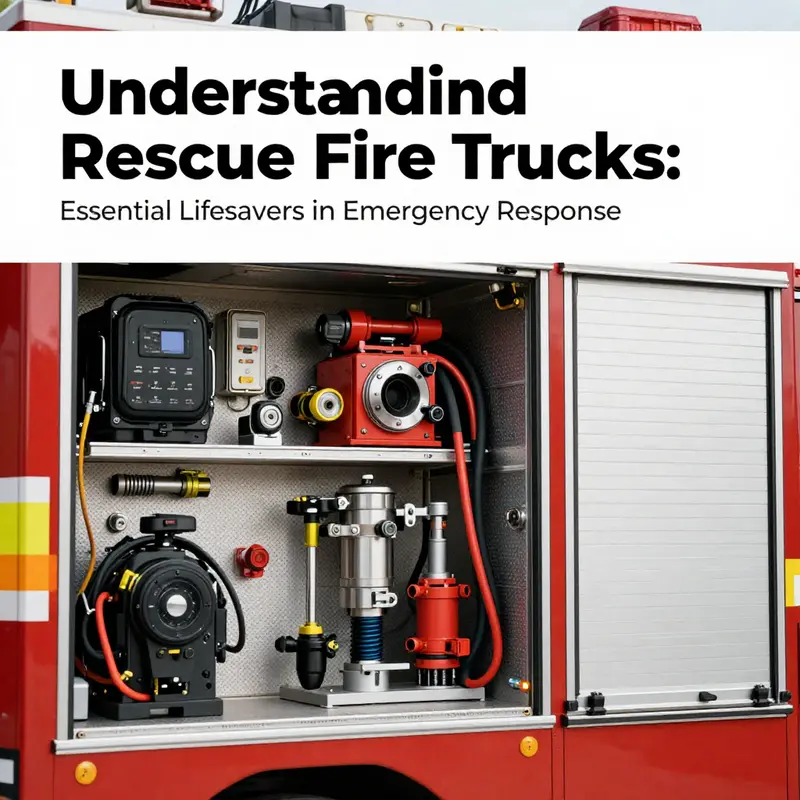

At its heart, the rescue fire truck foregrounds advanced rescue equipment. The defining tools are hydraulic rescue devices—cutters, spreaders, and rams—that can shape metal, pry apart wreckage, and create pathways to reach victims trapped inside vehicles or collapsed spaces. These tools are not toys; they are heavy, precisely engineered devices designed to withstand extreme force while delivering controlled, predictable results. In the field, responders use hydraulic cutters to slice through steel frames with surgical precision, then deploy spreaders to push apart wreckage without compromising the stability of a survivor, and employ rams to lever apart doors or panels that resist traditional prying. Complementing these are pneumatic air bags and lift systems that can lift, tilt, or stabilize heavy objects, allowing rescuers to shift loads gently and avoid further harm to those inside. A sophisticated winching setup adds another layer of capability, enabling the truck to pull vehicles from precarious angles, drag debris clear of an access point, or even self-recover when the vehicle becomes stuck after a complex extraction.

The inventory inside a rescue truck is designed to be both wide and deep, with specialized cutting and spreading tools that can handle reinforced materials and unusual configurations. The crew can encounter anything—from compact urban car wrecks to large commercial vehicle incidents to confined spaces behind collapsed walls. The tools must be versatile enough to manage a range of obstacles, including glass, steel, aluminum, and composite materials, and they must operate under hot, smoky, or windy conditions where visibility and dexterity are compromised. This is why the layout beneath the cabinets is intentionally modular and methodical. Each tool has a defined place, with quick-release mechanisms, labeled compartments, and safety interlocks that keep equipment secure during transit and accessible at the moment of need. The result is a workflow where responders transition from scene assessment to tool deployment in a tight sequence that minimizes delay and maximizes the chance of a successful rescue.

Alongside the hydraulic suite, the rescue truck carries a robust array of lifting and stabilization devices. Pneumatic bags—often arranged in a tiered system to accommodate different loads—provide a controlled means to raise a vehicle lid or create a cradle for a patient without shifting debris or provoking further injury. The same system allows responders to stabilize a wreckage before any cutting or lifting begins, reducing the risk that a moving mass will injure a trapped person or the rescuers themselves. The importance of stability cannot be overstated: even a slightly restless vehicle moving during an extraction can transform a survivable scenario into a fatal one. The lifting and stabilizing capability, when combined with cutting tools, creates a controlled sequence in which access is gained, a victim is stabilized, and medical care can begin as soon as respiration and circulation are supported.

No rescue operation is complete without the practical ability to move people and objects, and here the vehicle’s towing and pulling systems shine. Strong winches, combined with dedicated pulling lines and rigging gear, broaden the reach of the crew when straight-line extraction is not possible. Mentally, this is the difference between being able to remove a person from a crushed cabin and having to wait for heavy equipment to arrive. In many urban scenes, time is measured in minutes, not hours, and the right pulling setup can reduce that clock dramatically while maintaining safety margins. The interplay between lifting, stabilizing, and pulling is delicate work that demands both discipline and experience. The rescue truck concept embraces this choreography by ensuring that all components work together in a predictable, repeatable pattern.

Beyond raw power, the vehicle is also an on-call medical technician. A comprehensive medical kit, rapidly accessible first-aid supplies, and an assortment of life-support devices turn the truck into a mobile field clinic. Crew members train to perform immediate clinical actions—airway management, hemorrhage control, and task-specific interventions—while never losing sight of the broader scene safety. Respiratory protection and self-contained breathing apparatus equipment are essential, especially in environments with smoke, toxic fumes, or low oxygen levels. Personal protective equipment is not merely protective gear for the crew; it is an integral part of the operational envelope that makes it possible to work in dangerous zones without compounding risk. In many departments, the medical capability of rescue teams is synchronised with the work of the vehicle’s hydraulic and lifting systems, allowing a seriously injured person to be treated en route to a hospital or even while the vehicle remains in dynamic interaction with the rescue site.

The technical prowess of a rescue truck is incomplete without the sim‑plified, durable systems that keep it functional under harsh conditions. Onboard power supply is essential for tools, lighting, and electronics. A dependable generator or power system ensures that cutters, spreaders, pumps, and lighting remain available even when the earliest hours of an incident turn into a long night. High-intensity lighting is critical when a scene sits in shadows or when debris blocks natural light. The brighter the scene, the fewer mistakes the crew makes, and the easier it is to execute a precise extrication or stabilization sequence. The lighting is not merely for visibility; it is an extension of safety, enabling clear communication between team members and preventing missteps during critical moments.

Communication and command are the bedrock of effective rescue work. Integrated radios and data terminals connect crews to dispatch, other responding units, and the incident command. In major incidents, a mobile command post on a rescue vehicle can be deployed to plan, coordinate, and document operations as they unfold. This mobile command center typically houses robust communication gear, a workstation surface, maps or digital planning tools, and enough space for briefings with other agencies or units. The ability to coordinate in real time with fire suppression teams, EMS, law enforcement, and transportation services is not an optional feature; it is a life-supporting component that keeps the entire operation coherent under stress.

Inside the vehicle, modular storage and organization systems transform a busy scene into a manageable workspace. Aluminum alloy modular compartments hold a wide range of tools in an orderly, labeled system. The layout is designed to optimize speed: responders know exactly where to reach, and they can access the right tool in seconds rather than scrambling through a tangle of gear. At the same time, the storage system protects equipment during transit, preserving tool integrity and reducing the risk of accidental injury to the crew. The modular approach also makes it easier to tailor a rescue truck to the local needs. A department facing more vehicle extrications might prioritize heavier cutting tools and more airbags, while another that encounters frequent hazardous materials incidents might emphasize containment kits and spill response gear. Either way, the core principle holds: tooling is arranged for efficiency, safety, and fast action.

The operational reality of a rescue truck hinges on a careful balance between capability and practicality. In many urban environments, where traffic, high-rise corridors, and dense construction create challenging access, the rescue apparatus acts as a force multiplier. The truck’s combination of rapid extrication tools, stable lifting systems, and integrated medical care lowers the threshold for survival in victims who sustain life-threatening injuries during crashes or collapses. The design philosophy is not about replacing traditional firefighting but about expanding it—creating a seamless bridge between defeating flames and rescuing people who would otherwise be trapped beyond reach. Some departments operate a dual‑unit model, with a dedicated rescue vehicle alongside a separate engine, while others rely on a combined pump-rescue platform. Either configuration aims to maximize response time and scene control, making sure that when the initial alarm comes in, responders are equipped to answer not just with water, but with a complete set of life-saving tools.

A crucial but often overlooked thread in this narrative is the training and ongoing proficiency that keep the rescue truck truly effective. The most impressive fleet of tools is only as good as the crew using them. That means rigorous, repetitive practice with controlled extrications, staged collapses, and simulated hazardous materials scenarios. Training reinforces not just the mechanical steps but the judgment that guides when to cut, lift, or stabilize, and when to pivot to medical care. In this regard, the rescue truck is as much about human readiness as it is about hardware. The vehicle invites a cycle of practice that mirrors the unpredictability of real incidents—scenarios where the plan must adapt in real time to shifting conditions, new hazards, or changes in victim status. Evidence of that adaptive capability appears in the way crews integrate tools with medical care and scene management, coordinating with dispatch to prioritize life-saving actions while maintaining crew safety. For many teams, a key element of this readiness is a culture of continuous improvement—retaining lessons learned from past calls, refining standard operating procedures, and investing in training infrastructure such as dedicated facilities or training towers that allow responders to rehearse the most challenging extrications in a controlled environment. This emphasis on training is why a rescue truck becomes more than a vehicle; it becomes a platform for developing judgment, teamwork, and resilience under pressure. A practical example of this culture is the use of specialized training facilities that let responders practice controlled interactions with heavy tools, fall protection, and patient care under timed conditions, ensuring that when a real alarm arrives, the crew is not learning on the job but applying mastery in a high-stakes setting. For readers curious about how agencies cultivate this readiness, the journey from classroom to crane-free site to active duty traces a path through hands-on drills, scenario-based rehearsals, and the continual sharpening of instincts gained through repeated exposure to challenging simulations. The effect is a team that can move with confidence and composure, even as the environment around them remains uncertain and dangerous.

The rescue fire truck, then, emerges as a synthesis of force and precision. It is a vehicle designed to confront the most demanding scenes with a patient, methodical discipline that treats every action as a calculated move toward saving lives. It sits at the intersection of technical rescue, emergency medicine, and incident command, a mobile toolkit where power and care converge in real time. It invites responders to imagine a scene not as a single problem—fire, cut, or collapse—but as a chain of interconnected tasks that must unfold in a tightly choreographed sequence. In this sense, the rescue truck is a symbol of modern emergency response: a platform built to adapt, a kit designed for speed with a backbone of safety, and a crew trained to translate equipment into outcomes when every second counts. For professionals, this approach is the standard against which all other response strategies are measured, and for observers, it offers a window into how contemporary fire services meet the evolving demands of urban life and beyond.

As with any complex system, the value of a rescue truck is not merely in its components but in how those components interact under pressure. The hydraulic tools and airbags must synchronize with the stabilization methods and the patient’s medical needs. The lighting and power systems must sustain both the crew’s visibility and the operation of medical devices, while the radio network ensures that the right voices are heard at the right moments. The equipment must survive the demands of exposure, vibration, heat, and damp conditions, and it must do so without compromising safety or reliability. This is why design choices emphasize not only capability but durability and maintainability. It also explains why some departments invest more heavily in modular storage and rapid-access compartments: the fastest way to save a life is to reduce the moment you spend searching for the tool that makes the difference. In practice, every rescue call becomes a test of the truck’s readiness and the crew’s composure, a reminder that the cost of delay is measured in human lives, sometimes with long-term consequences for families and communities.

In closing, a rescue fire truck is a specialized, rapidly mobilized, and highly capable platform that extends a fire department’s reach beyond extinguishing flames. It is a unified system where heavy-duty rescue equipment, on-board medical capability, power and lighting, communication and command, and modular organization converge to create a responsive, adaptable force on wheels. The vehicle’s value emerges most clearly when it enters a scene already activated by training and seasoned judgment, allowing responders to translate complex equipment into a safe, efficient rescue operation. The next chapters will further explore how departments tailor these vehicles to their geographic realities, budgets, and incident profiles—keeping the focus on what matters most: protecting life in every kind of emergency, when time is the one resource we cannot replace. For readers seeking practical insights and deeper engagement with training culture, see the related resources on firefighter training tower programs, which illustrate how teams prepare for the exact challenges described here. firefighter training tower.

External resource for further reading: https://www.nfpa.org

The Lifeline on Wheels: How Rescue Fire Trucks Reframe Emergency Response Beyond Fire Suppression

When a call comes in that a vehicle is overturned, a person is trapped in a collapsed trench, or a hazardous material spill threatens nearby civilians, the arrival of a rescue fire truck signals a shift in strategy. It is a vehicle built not merely to spray water, but to apply meticulous human skill in tight, perilous spaces. The rescue truck is a specialized tool in the firefighter’s arsenal, designed to address moments when time, access, and safety converge to determine life or death outcomes. In these moments, the chassis itself becomes the first line of defense, carrying a compact, precisely curated toolkit and a crew trained to deploy it with speed and care. This is what sets a rescue vehicle apart from the engines that rush to douse flames: a rescue unit is a mobile workshop of lifesaving technique, optimized for operations where the objective is to free a trapped person with minimal further injury while stabilizing the scene for medical teams and other responders to take over.

The architecture of a rescue fire truck mirrors its mission. The vehicle’s interior layout prioritizes rapid access to a wide range of tools, with hydraulic systems and power sources arranged so that operators can reach cutters, spreaders, and lifting devices without barriers. The phrase commonly used to describe the core repertoire—hydraulic rescue tools, airbags, lifting bags, and rigging gear—signals that these trucks are built to pry, lift, stabilize, and extract. The spreaders and cutters, reactors of force, are the physical levers that unlock vehicles tangled in wreckage. The rams provide a controlled push to create an opening small enough for a rescuer to work within. These are not the devices of a demolition crew; they are the deliberate instruments of a precise, measured extraction, applied under the stress of a ticking clock and the uncertainty of each new twist in the scene.

Yet equipment alone cannot explain the rescue truck’s impact. The real difference lies in how the crew combines tools with technique to achieve outcomes that standard firefighting can’t guarantee. A rescue crew operates under the assumption that every minute matters, and their training emphasizes speed without compromising safety. They perform scene assessments that combine quick risk appraisal with a methodical plan, mapping out the safest approach to access a victim while preserving the structural integrity of the vehicle or space. This cognitive choreography—size up, plan, adapt—occurs while rescuers don essential safety gear, coordinating with incident command, EMS, and, when necessary, hazardous materials specialists. In practice, the rescue truck becomes a hub of coordination as much as a repository of hardware.

A well-equipped rescue truck carries more than its cutting tools. It brings in a suite of stabilization devices designed to hold a vehicle or object in place so that occupants can be approached safely. Airbags and lifting devices can gently elevate a heavy bumper, wheel, or roof segment, reducing the risk of sudden shifting that could worsen injuries. Rope and rigging gear allow rescuers to descend into unknown spaces or to anchor lines for high-angle or confined-space operations. The presence of ventilation equipment serves a twofold purpose: clearing toxic fumes and reducing heat buildup during long extrication sequences that exhaust both victims and responders. Every piece of gear is chosen for its reliability under pressure and its compatibility with other components so that a rescue operation can progress in a controlled, predictable fashion—even as the scene remains unpredictable.

Embedded in the truck’s equipment is a medical dimension that reflects the reality of modern rescue work: the first minutes after a crisis are critical for the patient. In many departments, the crew includes personnel trained to deliver paramedic-level care or advanced first aid on the way to hospital care. This medical capability ensures that life-saving interventions, such as airway management, bleeding control, or rapid assessment of injuries, can begin immediately at the scene. The transport of patients remains a central objective, but in a rescue scenario, medical action often travels with the patient in the same vehicle or is folded into the scene’s overall response rather than waiting for a separate unit to arrive. The goal is not to replace hospital care but to bridge the gap between incident stabilization and definitive treatment, thereby improving outcomes during a window that is measured in minutes rather than hours.

The lighting and communications systems on a rescue truck reinforce this continuous, coordinated effort. High-intensity lighting illuminates work zones that may otherwise be shrouded in darkness or shadows caused by wreckage, collapsed structures, or dense smoke. This visibility is not purely for comfort; it is a safety mechanism that reduces the chance of secondary injuries to both victims and responders. Integrated communications allow the crew to relay updates to incident command, coordinate with EMS, and synchronize actions with other responding units. In situations that involve multiple agencies or complicated terrains, clear, reliable communication becomes as essential as the tools in the truck’s toolbox.

Another crucial facet of a rescue truck’s effectiveness is its mobility and accessibility. In densely populated urban centers, narrow streets, traffic, and closed lanes can delay larger apparatus. Rescue units are designed with compact dimensions and a distribution of weight that keeps the vehicle agile yet sturdy on a variety of road surfaces. The braking, suspension, and power systems are tuned to support heavy equipment without sacrificing maneuverability. In settings such as highway collisions, off-road incidents, or industrial facilities with uneven floors, the truck must reach where others cannot, then operate as a stable platform for complex manipulations.

Some fire departments adopt a policy of dedicated rescue trucks, while others opt for a combination pump/rescue approach that merges firefighting and rescue functions into a single chassis. Each model has its rationale: a standalone rescue unit can maximize rescue-specific readiness, with a crew trained and organized around extrication and stabilization tasks; a combination unit prioritizes resource efficiency and rapid transition from life-saving extraction to fire suppression if the scene evolves. In either case, the strategic purpose remains the same—expand the department’s capability to address non-fire emergencies with professionalism, speed, and a focus on preserving life.

The operational value of this specialization becomes clearest when we consider the kinds of incidents that dominate modern emergency response. Vehicle extrications represent a recurring need in urban environments, where everyday roads intersect with high traffic volumes and complex vehicle designs. Confined-space rescues sometimes arise in industrial settings or collapsed structures where access is severely limited. Trench rescues demand rope work, stability considerations, and the ability to manage space constraints without triggering further collapse. Hazardous-material scenarios require containment, ventilation adjustments, and careful progression to avoid exposure. Across these contexts, the rescue truck provides a portable command post of sorts: a moving center of gravity that anchors the immediate tactical response and supports the evolution of the incident toward a safer, more recoverable outcome.

The operational importance of a rescue truck also extends to the broader strategic fabric of a department’s readiness. Having a specialized vehicle signals to communities that responders are prepared not only to fight fires but also to handle the non-structural emergencies that can overwhelm a scene if left unaddressed. It expands the department’s jurisdiction in practice, turning it into a more versatile partner for other agencies and for public safety at large. In urban areas where traffic accidents and structural incidents are common, this versatility translates into tangible gains in time-to-access, scene stabilization, and patient safety. The presence of a trained rescue crew—often operating in tandem with incident command and EMS—helps to de-silo responses and creates an adaptable framework where technical rescue, medical care, and risk management are integrated rather than sequential.

Discussions about rescue vehicles rarely stay at the level of hardware alone. The most enduring takeaway concerns the people who operate and maintain these systems. A rescue crew is typically composed of firefighters who are cross-trained for technical rescue work and who maintain ongoing relationships with paramedics or EMS professionals. Their training emphasizes hands-on practice in controlled environments that mimic the challenges of real scenes: improvisation with limited space, rapid decision-making under stress, teamwork that crosses divisions, and adherence to safety protocols that protect both responders and victims. This human dimension matters because equipment can fail, conditions can deteriorate, and plans can be outpaced by the complexity of a scene. In those moments, the crew’s experience, communication, and composure become as critical as the tools they wield.

The integration of rescue trucks into a department’s fleet further underscores the broader trend toward comprehensive readiness. Some departments maintain a robust reserve of rescue apparatus so that multiple calls can be managed in parallel, while others invest in regional collaborations that share resources across municipalities. Either model reflects a philosophy: to reduce the time between recognition of a need and the delivery of a trained, equipped, and coordinated response. When a rescue unit rolls to a scene, it carries with it a philosophy of care that begins the moment of arrival and continues through every minute of extrication, stabilization, and transport. Even the most intricate technical maneuvers become more manageable when teams approach them with a well-practiced routine, a clear chain of command, and a shared sense of purpose that prioritizes life above all else.

This chapter’s synthesis points toward a fundamental truth: rescue fire trucks embody a shift in emergency response culture. They are not a denial of traditional firefighting duties but a widening of the mission to honor the most urgent need at many scenes—saving lives through swift technical action, careful patient handling, and robust scene management. The equipment is specialized, but the underlying ethos is universal: responders must meet danger with preparation, precision, and a steady focus on minimizing harm while maximizing the chance for a favorable outcome. In urban wards and regional corridors alike, the rescue truck is the embodiment of that ethos in motion, a mobile, reliable, and adaptable engine of rescue that redefines what it means to protect, to save, and to restore safety when the clock is ticking.

For readers seeking a broader perspective on how these vehicles fit into the larger fabric of a department’s strategy and training, the Fire Rescue blog offers articles that explore vehicle selection, crew readiness, and policy considerations in practical terms. Fire Rescue blog.

External reference for technical overview: https://www.firefightingequipment.com/rescue-fire-trucks-explained/

Beyond Water: How Technological Innovations Redefine the Rescue Fire Truck

When people think of a fire truck, they often picture a gleaming apparatus delivering torrents of water to extinguish flames. In reality, the rescue fire truck sits at the intersection of emergency medicine, technical rescue, and incident command. It is the vehicle that can shift the tempo of a scene from chaos to control, from improvisation to method. As urban landscapes grow denser and accidents become more complex, the rescue pumper has evolved from a mere water-delivery tool into a mobile, autonomous, and highly capable system that combines cutting-edge electronics, intelligent software, and precision engineering. The chapter that follows traces this evolution not as a checklist of gadgets, but as a narrative of how technology reshapes every phase of a rescue—from the moment a call is received to the after-action analysis that informs the next response. It is a story of endurance, adaptability, and the careful orchestration of tools that keep responders safe while expanding their ability to save lives under pressure.

At the heart of modern rescue fire trucks is a shift toward energy efficiency and reliability in the harshest conditions. The rise of new energy powertrains—where electric drivetrains and advanced battery systems power the vehicle—has driven a parallel revolution in how these trucks manage endurance on prolonged missions. AI-enabled systems continuously analyze real-time driving data and the vehicle’s mechanical health to optimize charging strategies, thermal management, and energy distribution across essential subsystems. The result is more predictable range, less downtime for maintenance, and a vehicle that remains mission-capable during extended rescue operations that stretch into the night or across challenging terrains. The emphasis is not on replacing firefighters with machines but on equipping them with smarter tools that extend human reach, reduce fatigue, and increase the margin for error margin in high-stakes moments.

This technological shift is not limited to propulsion. Inside the cab and along the chassis, embedded sensors monitor vitals of the rescue operation itself. Real-time telemetry feeds from hydraulic tools, air supply systems, and stabilizing airbags create a live picture of the work being done. These data streams support incident command by providing a shared situational awareness that is both granular and scalable. For crews in vehicles, the feedback loop becomes faster and safer: tool actuation can be synchronized with lifting or cutting sequences, while battery-powered tools can be managed to maintain consistent performance as demands fluctuate. In practice, this means that the response to a vehicle crash, a building collapse, or a hazardous materials incident can unfold with fewer surprises. The truck becomes a moving command center, capable of balancing speed with precision, power with control, and heavy equipment with crew safety.

The capacity to perform technical rescues efficiently rests on a carefully curated suite of hydraulic, lifting, and stabilization systems. Yet the newest generations of rescue trucks fuse these capabilities with intelligence. A networked suite of sensors not only monitors tool health but also assesses scene physics—such as the risk of structural movement or shifting loads—so responders can time their actions to minimize secondary injuries. When conditions change, the vehicle’s onboard computer can adapt, re-prioritizing tasks and reconfiguring sequences to keep the operation on a safe track. The engineering philosophy here is holistic: tools, humans, and information coalesce in a single platform that understands the arc of the incident and responds accordingly.

These abilities are complemented by a new kind of versatility that has become essential in contemporary emergency response: the integration of decontamination and medical functions into the same platform. The idea of a single vehicle that can both rescue and decontaminate reflects a broader trend toward modular, multipurpose capabilities. In hazardous environments, even the most well-intentioned interventions can spread contamination or expose responders to risk. Modern rescue trucks address this by incorporating micro-positive pressure protection not only in the driver’s cabin but also in the work area. This protective architecture creates a controlled environment where responders can operate with higher confidence, entering zones that would have been regarded as inaccessible in the past. Detection and decontamination are fused through data fusion technology—an approach that collects signals from air monitoring instruments, surface swabs, and environmental sensors to guide immediate decision-making. The smart algorithms behind this fusion can match decontaminants to specific contaminants, accelerating the protection and recovery of emergency personnel and—crucially—minimizing the time spent in dangerous zones.

The multipurpose nature of these vehicles raises some practical questions about how best to deploy and sustain them. In many regions, a single vehicle might be called upon to perform both firefighting and rescue tasks, while in others, separate units are maintained to maximize efficiency and readiness. The strategic choice hinges on local hazards, urban density, and the availability of trained personnel. Regardless of the organizational model, one principle remains constant: the vehicle must be able to move quickly, operate safely, and adapt to a broad spectrum of emergencies. To that end, new energy powertrains, paired with robust energy management strategies, ensure that even during back-to-back calls, riders and responders can rely on steady performance. The result is not simply a more capable truck, but a more reliable partner in the field, one that can be deployed at a moment’s notice with equipment ready to scale from cutting through metal to stabilizing a patient in minutes.

Parallel to the hardware advances are breakthroughs in software and analytics that transform a rescue mission into a coordinated, data-driven operation. For instance, AI-enabled video and data analysis tools are shedding new light on how to manage scenes, preserve evidence, and support faster decision-making. In the aftermath of fires or industrial incidents, investigators often face a labyrinth of visual material—burn patterns, debris fields, and camera footage from multiple vantage points. AI-based analysis can perform intelligent search, contour extraction, image measurement, and brightness segmentation to reconstruct scenes with a level of precision that supports credible forensic interpretations. Although these systems originate from broader research into smart video analytics, their application in the fire service offers a potent new lens for understanding what happened, why it happened, and how it can be prevented in the future. The practical impact is twofold: it accelerates accountability and it frees investigators to focus on interpretation and context rather than manual sifting through countless frames.

These digital tools are not mere add-ons; they represent a paradigm shift in how rescue work is planned, executed, and reviewed. The integration of advanced analytics with field hardware enables a more proactive posture. Quick, real-time decisions become possible because the system can compare current sensor readings with historical baselines, models of fire behavior, and known risk profiles for specific materials. A commander can see, in near real time, the trade-offs between prioritizing victim access, maintaining structural integrity, and preserving evidence. Firefighters, in turn, gain a safety net: if anomalous readings indicate a potential tool failure or a rising hazard, the vehicle can adjust its sequence and call for additional resources before escalation occurs. In short, the rescue fire truck has become a mobile, intelligent platform that augments human expertise rather than replacing it.

The role of the vehicle as a data hub is reinforced by a broader ecosystem of interagency collaboration and training. As these machines become more capable, the value of standardized data formats, interoperable communications, and shared situational awareness becomes clear. Incident command systems integrate feeds from the rescue truck with those from aerial units, hospital networks, and public safety communications centers. The instantaneous sharing of location data, casualty status, and tool usage charts contributes to a smoother, more efficient operation. It also helps agencies calibrate training programs and maintenance schedules to reflect the realities of modern rescue work. The effect is a virtuous circle: field innovations inform policy and education, while standardized procedures push for reliability and safety across jurisdictions.

This is why the idea of customized, adaptable platforms resonates so strongly with modern fire departments. The ability to tailor a rescue truck to specific regional needs—whether through improved off-road capability, enhanced decontamination modules, or a particular mix of hydraulic tools—underlines a broader principle: technology must be accessible, maintainable, and scalable. A recent wave of design thinking in the field emphasizes modular bodies and configurable control interfaces, allowing departments to upgrade components as new capabilities emerge without replacing the entire vehicle. This approach also supports global equity in emergency response. In places where resources are stretched, a carefully chosen mix of technologies can deliver outsized improvements in safety and effectiveness. The aim is not to chase every new gadget but to curate a coherent, resilient toolkit that grows with the department over time. For departments considering such an investment, one concrete path is to explore customized firefighting vehicle solutions that are designed with diverse scenarios in mind and that balance performance, cost, and long-term support. These considerations deeply influence program decisions, vehicle procurement, and how responders are trained to operate the fleet on day one and during years of service. Customized fire trucks for developing countries—comprehensive solutions for diverse scenarios

The trajectory of these innovations also reframes the way we think about the value of the rescue truck in the broader public-safety ecosystem. Rather than a single-action tool, the modern rescue vehicle behaves as a living system—an instrument that absorbs input from sensors, translates it into actionable intelligence, and acts in service of multiple missions. When a call comes in for a vehicle crash, the truck can deploy cutting tools, stage airlifting devices, and prepare a medical station on the roadside. If a hazmat scenario unfolds, it can ratio the response from decontamination modules, adjust air-filtering sequences, and coordinate with a nearby hospital’s rapid triage team. If investigators need to reconstruct a scene after the fact, the same platform stores high-fidelity data streams that can be mined to understand the sequence of events. The unifying thread is an emphasis on reliability, safety, and speed—three attributes that define emergency response at its best.

The practical implications of this convergence are nuanced and require careful stewardship. Fire departments must balance the allure of sophisticated technologies with the realities of maintenance, training, and budget cycles. Electric and hybrid powertrains, for all their potential to improve endurance, demand specialized maintenance expertise and supply chains. Decontamination systems require routine validation to ensure efficacy and safety. AI tools need thoughtful governance to protect privacy and ensure that algorithmic outputs remain interpretable to human operators. Yet when managed with disciplined governance, the combination of energy efficiency, intelligent control, and data-driven workflows can sharply reduce response times, minimize exposure to hazards, and improve outcomes for victims and responders alike. The chapter of rescue technology is not a triumph of gadgets but a sustained effort to align capability with need—preserving the human element at the center of every mission while expanding what is possible on the ground.

The most compelling part of this evolution is not the novelty of each feature, but the emergent capability that comes from their integration. When hydraulic tools, battery management systems, decontamination workflows, and forensic-analytics platforms act in concert, the rescue team gains a shared mental model of the incident. The truck’s sensors become a common thread that ties together the medical crew, the technical specialists, and the incident commander. This coherence translates into smoother transitions—from rapid extrication to decisive medical care, from scene stabilization to evidence preservation, from tactical planning to post-incident learning. It also means that responders can operate with greater confidence in inherently unpredictable environments. The vehicle thus contributes not only to the mechanics of rescue but to the psychology of rescue—reducing cognitive load, supporting better decisions, and enabling crews to focus on people rather than equipment.

In this sense, the modern rescue fire truck embodies a rare blend of resilience and adaptability. It is engineered to endure the most demanding conditions, to function with minimal downtime, and to provide intelligent support across a spectrum of emergencies. Yet it also remains a human-centered platform, designed to extend the capabilities of firefighters rather than supplant them. Every innovation serves a clear purpose: to accelerate rescue, to safeguard life, and to create a safer, more predictable environment for both the public and the responders who stand between danger and relief. As these vehicles continue to evolve, the line between vehicle, tool, and assistant blurs. The result is a rescue system that can be deployed with the same urgency, the same compassion, and the same commitment to excellence that define the firefighting profession at its best.

For readers seeking a broader look at how these trends are shaping practice around the world, this chapter connects with ongoing discussions in field training, safety standards, and cross-border collaboration. The integration of AI, renewable energy, and multipurpose capabilities is not a distant future; it is unfolding in departments that recognize the benefits of a well-timed, well-coordinated, and well-supported response. The rescue fire truck becomes, in effect, a platform for continuous learning—an engine for innovation that keeps pace with changing risks while preserving the core mission: to save lives when seconds count. In practicing this balance, fire services build not only more capable equipment but more capable teams, who carry forward a culture of safety, reliability, and adaptability that will sustain communities for generations to come.

External resources offer additional perspectives on these developments. For readers who want to explore a broader synthesis of technology-driven rescue innovations and their societal implications, a detailed overview is available at the external source linked here. This background helps contextualize the descriptions in this chapter and situates the rescue fire truck within a wider landscape of public safety, urban resilience, and data-driven governance. https://www.sohu.com/a/578634757_121225

Final thoughts

Rescue fire trucks are critical assets in emergency response, integrating advanced features, operational capabilities, and cutting-edge technology. Their role extends beyond merely firefighting; they are lifesaving devices that ensure timely medical assistance and technical rescues. Understanding their significance reinforces the importance of investing in such specialized vehicles for communities in need. The next time you see a rescue fire truck, remember its complexity and the lives it may save.