Fire/rescue apparatus are specialized vehicles crucial for effective emergency response, providing essential tools for firefighters and rescue operations. This article explores the various components, advanced technologies, operational roles, the significance of Personal Protective Equipment (PPE), and the environmental and safety regulations influencing their design. By examining these elements, we underscore the importance of these apparatus in ensuring swift and effective responses to emergencies.

Inside the Moving Command Center: The Components That Make a Fire/Rescue Apparatus a Lifesaving Mobile Command Post

A fire/rescue apparatus is more than a vehicle; it is a mobile command post designed to translate urgent, high-stakes situational information into decisive action. Its success rests on a carefully engineered balance of propulsion, water handling, tool capability, and the capacity to support responders as they move through smoke, heat, and unpredictable hazards. From the moment the apparatus leaves the station, every component operates as part of a cohesive system whose aim is to reach the scene rapidly, sustain the firefight, and protect lives, both of the public and of the responders who carry out the mission.

The backbone of this system begins with the engine and chassis, the heart and spine of the vehicle. A robust engine provides not only speed and acceleration but also the ability to tow heavy equipment and maintain performance under demanding conditions. This is essential when responding through dense traffic, diverse terrain, or challenging urban environments. The chassis that supports the engine must be designed to endure the racking forces of off-road conditions, uneven surfaces, and the repeated stresses of rapid acceleration and braking. While the specifics vary by manufacturer and model, the guiding principle is clear: a durable platform that remains stable under load, even when the water, foam, and equipment compartments are fully stocked.

Water remains a central element of the fire/rescue apparatus, and its management is a study in efficiency and reliability. A large water tank paired with an integrated pump system allows crews to begin suppression efforts quickly, often before a hydrant can be secured or a water shuttle operation established. The pump must deliver a steady stream at sufficient pressure to reach the most distant nozzles yet be controllable enough for smooth operation at the nozzle during active suppression. When foam or other specialized agents are needed, the system can switch modes to deliver the appropriate concentrate, expanding the range of conditions under which the crew can safely and effectively attack a fire. The ability to draw water from multiple sources, including hydrants or external tanks, adds a layer of resilience that is crucial when supply lines are disrupted or when access is limited by the environment. The importance of rapid water diversion—getting water to the fire quickly and then adjusting the flow as conditions evolve—cannot be overstated. In many operations, swift water management can turn the tide of a building fire, limit escalation, and protect adjacent structures.

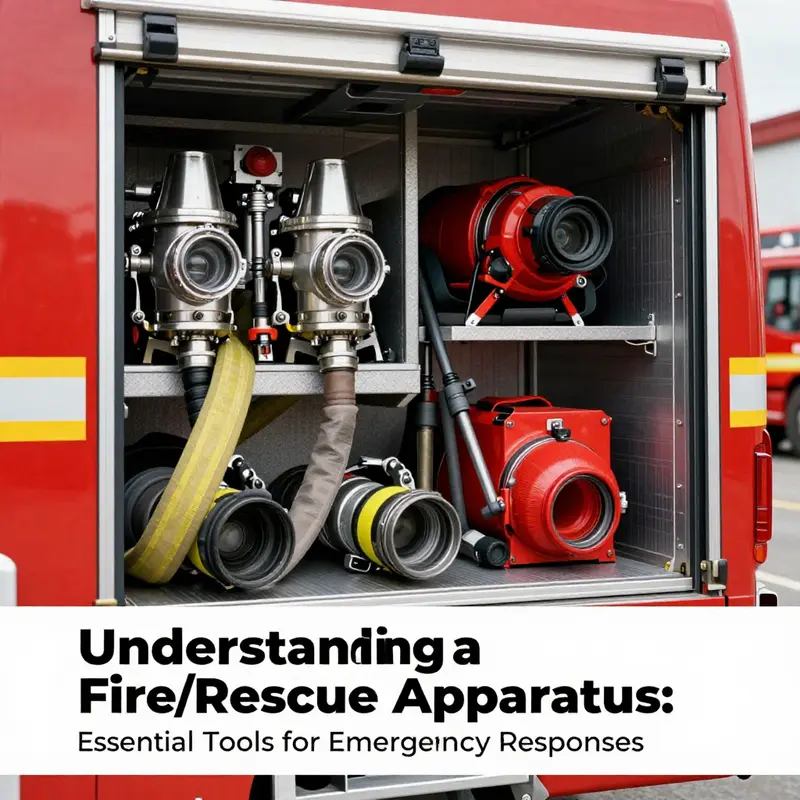

Beyond water delivery, the apparatus carries a suite of firefighting tools that enable responders to adapt to evolving scenarios. Hoses and nozzles remain fundamental, with attachments designed to permit a range of spray patterns, from a broad fog to a focused solid stream. Portable extinguishers, classified by fire type, provide a first line of defense for initial attack and can prevent a small fire from becoming a larger catastrophe while crews set up more robust suppression tactics. The layout of these tools emphasizes rapid access. Compartments are organized to minimize search time, and crews are trained to reach for the right tool in seconds, not minutes. The on-board systems also include communication devices and navigational aids that connect the scene to the command center, another critical thread in the fabric of a coordinated response.

Rescue operations introduce a specialized dimension to the apparatus, expanding its role from suppression to rapid extrication and technical intervention. Hydraulic rescue tools—commonly referred to as the jaws of life—are the most iconic element in this category. Spreaders, cutters, and rams enable responders to breach obstructions, pry apart crushed metal, or create openings for access and egress. The power, precision, and speed of these tools directly influence outcomes in vehicle crashes or collapsed structures. In addition to hydraulic tools, a well-supplied apparatus carries airbags, winches, and cutting torches, among other devices, to address a spectrum of mechanical and structural challenges. Each item is selected for reliability and compatibility with the others, ensuring that a toolbox built for one scenario remains useful across a broad array of emergencies.

A modern fire/rescue apparatus also places significant emphasis on medical readiness. An onboard medical kit complements the field care provided by firefighters and emergency medical technicians. While it cannot replace a hospital, it ensures immediate life support—airway management, bleeding control, shock mitigation, basic airway adjuncts, and essential medications where appropriate—so that patients receive timely care while en route to definitive treatment. This medical capability reinforces the concept of the apparatus as a mobile command post that can stabilize casualties and sustain compassionate, skilled care through the critical minutes after a call.

Organization within the vehicle is another essential layer that supports speed and safety. The design includes dedicated storage solutions and compartmentalization that protect gear from damage while exposing it to the quickest possible access. The goal is to minimize rummaging and preserve the rhythm of the operation. Properly organized storage also safeguards sensitive equipment from impacts and environmental exposure, which can degrade performance. A well-conceived layout helps reduce crew fatigue and cognitive load, letting responders maintain focus on the evolving tactical picture rather than chasing gear.

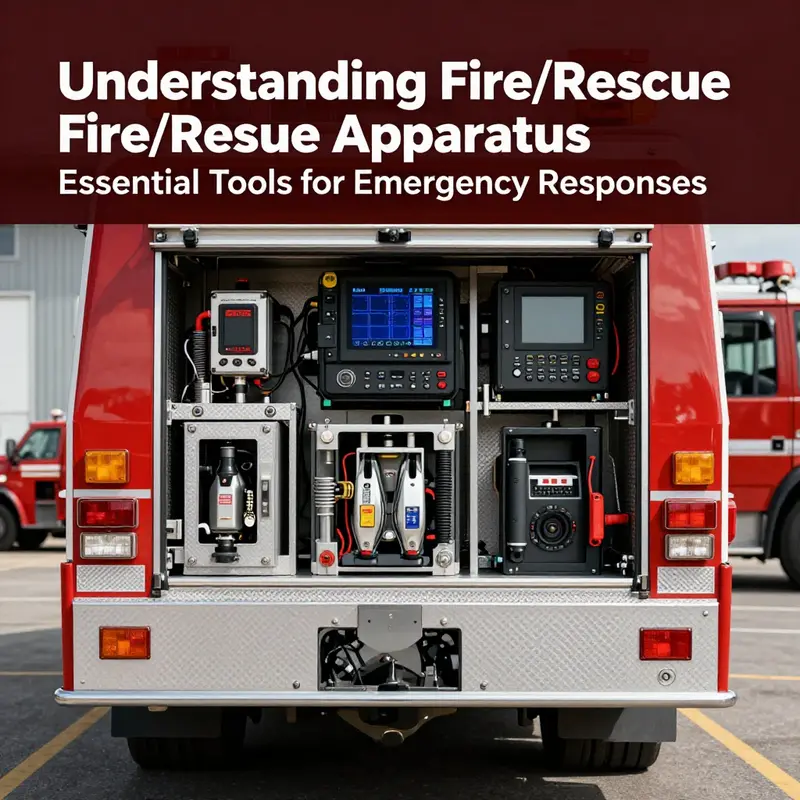

Lighting and communications complete the picture of the moving command center. Roof-mounted strobes and floodlights illuminate the scene during night operations or in smoke-occluded environments, enabling safer navigation and more precise tool handling. Clear, reliable lighting also improves visibility for incident commanders as they monitor the evolving situation, communicate with assets, and direct responders at ground level. The communications backbone—radios, GPS, and data links to the command post—binds the apparatus to the broader incident management framework. This connectivity is not merely convenience; it is a life-saving feature that supports coordination, reduces duplication of effort, and ensures a unified response across multiple agencies that may be working in concert on complex emergencies.

Beyond the core systems, several features extend the apparatus’s capabilities into specialized rescue and high-risk environments. A rear-mounted ladder or aerial platform gives responders vertical reach for high-rise rescues and for oversight of elevated fire conditions. Built-in foam systems support burning liquids and other challenging fire scenarios where water alone is insufficient. And for certain structures, there are even integrated mechanisms that enable vertical access for rescue teams, combining mechanical design with human ingenuity to reach people in difficult locations. These features reflect a broader philosophy: the apparatus must be ready for anything, and its equipment must promote safety through redundancy and versatility.

The design decisions that produce this readiness are not arbitrary; they reflect both historical lessons and evolving standards. Fire service guidelines and national safety organizations shape how components are specified, tested, and deployed. The emphasis is on reliability under stress, compatibility across a broad spectrum of operations, and the capacity for rapid evolution as new tools and techniques emerge. In practice, this means seamless integration across engine, pump, hoses, rescue tools, PPE, lighting, and communications. It also means maintenance programs that keep every system in harmony, with regular inspections, fault isolation, and proactive replacement of worn parts. The goal is not a static collection of gear but a coherent, living platform that supports responders as they navigate the unpredictable demands of a scene.

The complexity of a fire/rescue apparatus also invites a thoughtful conversation about adaptability and context. Departments operating in different climates, urban densities, or resource environments often tailor equipment configurations to match local realities. This is where a concept like customized firefighting vehicle solutions becomes meaningful. The idea is to balance capability with cost, ensuring that a given apparatus delivers the highest practical value for its operating context. For organizations exploring such adaptations, a bridge to long-term resilience is built on careful analysis of incident types, response times, and maintenance costs, followed by collaborative planning with manufacturers and service networks. See how these considerations are addressed in discussions about developing-country deployments, where solutions must be reliable, cost-effective, and fully supported, allowing communities to build robust response capabilities even in challenging settings.

For further perspective on the breadth of essential components and the types of fire trucks deployed across different jurisdictions, contemporary industry discussions emphasize the interconnectedness of suppression gear, rescue tools, medical readiness, and mobility. These discussions reinforce the view of the apparatus as a moving command center—an integrated platform designed to translate the chaos of an emergency into organized, purposeful action. The result is a vehicle that not only carries people and gear but also embodies the organizational capacity to orchestrate a complex response under pressure. While each department tailors its configuration to local needs, the core principles endure: rapid arrival, versatile water management, rapid access to specialized tools, effective life safety measures, and clear communications that unite responders and command at the scene.

As the scene evolves, so too does the need to adapt the equipment and tactics in real time. This adaptability rests on the combination of versatile components, disciplined operations, and ongoing training that keeps crews fluent in both the technical use of tools and the strategic thinking required to manage risk and save lives. Fire/rescue apparatuses are not static machines; they are dynamic platforms that reflect a continuous commitment to resilience, safety, and service. The more deeply communities understand and invest in these moving command centers, the more capable they become in meeting the wide array of incidents—from structural fires to urban search and rescue missions and hazardous material responses.

In sum, a fire/rescue apparatus is a carefully engineered system whose value emerges from the thoughtful integration of engine power, rugged chassis design, water management capabilities, a comprehensive suite of firefighting and rescue tools, medical readiness, organized storage, and robust lighting and communications. Each component is selected not in isolation but as part of a coordinated approach to incident response. The result is a vehicle that can be deployed quickly, operated safely, and trusted to support a team working at the edge of danger. When these elements work in concert, responders gain more than equipment; they gain a platform for leadership, for coordinated action, and for the saving of lives in moments that demand courage, skill, and teamwork. For readers seeking a deeper dive into the practical aspects of component selection and operational use, standard references such as the NFPA provide essential guidance on standards and best practices, underscoring the shared goal of safer communities through well-designed, well-maintained rescue equipment.

External reference: For additional context on essential components and types of fire trucks, see Firefighting News at https://www.firefightingnews.com/fire-rescue-vehicles/essential-components-and-types-of-fire-trucks/.

Seeing Through Smoke: How Advanced Technologies Redefine the Fire/Rescue Apparatus

Fire and rescue apparatus are more than lifeless metal on wheels. They are platforms that translate human judgment into swift, coordinated action under extreme conditions. At their core they remain specialized vehicles or equipment designed to deliver water, cut through obstacles, and carry responders to places others cannot reach. Yet the recent wave of advanced technologies is turning these machines into smart, integrative systems that extend perception, speed, and safety far beyond traditional expectations. The apparatus is no longer only about carrying hoses and pumps; it is about delivering situational awareness, predictive insights, and automated or semi automated capabilities that help responders make better decisions when every second counts. A crucial shift is the incorporation of thermal imaging technologies, which bring the hidden dynamics of a fire into clear focus. Thermal imaging cameras embedded in or mounted on the apparatus allow responders to see hot spots through dense smoke and darkness, locate victims who may be obscured by debris or smoke, and track the fire’s spread within a structure. Studies from recent years show that these imaging systems can reveal flame signatures almost immediately after ignition, enabling faster triage, more targeted entry, and a higher chance of preventing escalation in challenging environments such as high rise complexes or industrial facilities. This leap from relying on sight alone to integrating thermal data transforms decision making in the moment when it matters most, guiding hose placement, ventilation strategies, and rescue routes with a precision that would have been unimaginable a decade ago. Alongside TICs, automated fire detection systems are becoming more common inside and around the vehicle, linking sensors that monitor heat, smoke, and flame signatures with dispatch networks and GPS. The consequence is a chain of events that can begin before a fire becomes visually obvious, triggering alerts, guiding responders to precise coordinates, and enabling pre arrival coordination with command centers. The result is not merely faster response but a more reliable, data driven path to the scene that reduces information gaps and accelerates critical pre entry planning. Drones and robotics extend the reach of ground teams in a way that minimizes risk to human life while increasing the amount of actionable data available at the scene. Unmanned aerial vehicles equipped with infrared and high resolution cameras can map a burning structure, assess structural integrity, locate trapped occupants, and identify hazardous zones from above, all without exposing crews to heat or falling debris. Ground based robots can probe unstable areas, deliver lightweight supplies, or even assist in extinguishing efforts in corridors that would otherwise be inaccessible or dangerous for responders. These aerial and ground systems do not replace human skill; they augment it by providing a secure, real time feed that informs every tactical decision. Communication systems in modern apparatus have evolved into robust, encrypted networks that sustain data flow even where cellular service is weak or compromised. The idea is to create an on scene information ecosystem where commanders, crews, and nearby agencies share a common operating picture. This can involve mesh networks that keep vital communications intact as a rescue unfolds, enabling rapid dissemination of risk assessments, weather influences, and structural indicators to multiple teams at once. Paired with information analytic platforms, on board sensors begin to build dynamic risk models that help predict potential structural collapse, gas accumulation, or fire spread based on real time conditions and historical patterns. The upshot is a more proactive approach to safety that keeps crews out of harm while optimizing the sequence of actions taken during a volatile incident. These technologies are not single tools but facets of a broader modernization program that seeks to improve vehicle performance and crew safety through smarter design. Modern firefighting apparatus incorporate lighter yet durable materials, optimized suspension, and more maneuverable chassis so that large rescue vehicles can navigate tight urban landscapes and uneven terrain with greater ease. The use of composite materials reduces weight without compromising strength, while advanced suspensions deliver smoother rides and better stability when the equipment is deployed in challenging locations. Onboard power generation and auxiliary systems are increasingly common, enabling crews to sustain extended operations without external power sources. The net effect is an apparatus that can perform extended missions with fewer interruptions, a critical factor during large scale incidents where power needs and equipment demands fluctuate rapidly. The emphasis on mobility and resilience also reflects lessons from diverse environments, including dense urban centers and rural or off road settings where terrain can complicate access. In these contexts the ability to deploy pumps, monitors, and rescue tools quickly is inseparable from the chassis and suspension that carry them. The design philosophy is to ensure that response times remain short, that equipment can be deployed with minimal maneuvering, and that crews can exchange information with confidence as a scene unfolds. Another layer of evolution concerns the integration of automated and semi automated systems within the vehicle itself. Sensors monitor fluid levels, pump performance, and hydraulic pressures, and, when necessary, alert operators or automatically adjust settings to maintain optimal operation. Automated detection and response capabilities can also link to external infrastructure, such as building sensors or city wide emergency networks, to coordinate a wider, safer response. This level of integration means that the modern fire rescue unit behaves less like a solitary tool and more like a node in a network of intelligence that includes responders, building systems, and the broader emergency services ecosystem. As a result, the apparatus becomes a platform for rapid decision making that blends human expertise with machine precision, reducing the margin for error without diminishing the essential role of professional judgment. The practical implications of these advances extend across the spectrum of fire response. In structural fires, rapid detection, clear visualization through smoke, and precise water or foam deployment can dramatically improve the odds of saving lives and reducing property damage. In wildland contexts, mobility and fuel management trends in modern apparatus help teams reach remote or uneven terrain where fires tend to spread unpredictably. In industrial settings, hazard mapping and real time data sharing can illuminate complex risk factors, allowing responders to tailor their approach to the specific chemistry and layout of a facility. Urban search and rescue missions benefit from the combination of TICs, drones, and robotic delivery of essential equipment into confined spaces, enabling rescuers to locate victims and establish safe egress routes without prematurely exposing themselves to danger. The overarching principle is that these technologies do not exist in isolation; they interplay with established protocols, training, and the standards that govern firefighting practice. The National Fire Protection Association and similar bodies provide the guidelines that help ensure new systems enhance safety rather than introduce new risks through complexity. Training remains essential, both to interpret sensor data accurately and to act on it with discipline. Even the most advanced equipment relies on human judgment to translate information into effective action. In this sense, technology is not a replacement for expertise but an amplifier of it, enabling responders to conserve energy and attention for the most demanding moments of an incident. This balance—between human skill and machine assistance—drives ongoing research and development in the field. It also invites consideration of how technologies can be tailored to different operating environments and budgets. The industry has demonstrated that technology can be adapted for diverse circumstances, including developing regions where costs and terrain demand creative solutions. For instance, the concept of customized fire trucks that align capability with budget constraints and local conditions illustrates how advanced systems can be scaled without sacrificing essential performance. These approaches show that the core purpose of a fire rescue apparatus remains consistent: to maximize speed, safety, and effectiveness, while providing responders with the best possible information and tools. See in particular how tailored configurations can meet varied terrain and fiscal realities, showing that high tech does not have to mean high cost at every turn. Customized Fire Trucks for Developing Countries. The broader trajectory points toward a future where AI driven command systems, smarter PPE, and more integrated mission support become standard features rather than exceptions. This future holds promise for reducing time to intervention, improving survivor outcomes, and protecting responders from the hazards inherent to high risk environments. For readers seeking a deeper dive into how these technologies have been demonstrated and discussed in recent venues, recent coverage of the 2025 International Firefighting Exhibition offers a snapshot of cutting edge developments, including AI assisted command interfaces and next generation personal protective equipment that will shape practice in the years ahead. External resource: 2025 International Firefighting Exhibition Technology Preview.

On the Front Lines: How a Fire/Rescue Apparatus Orchestrates Response, Rescue, and Scene Leadership in Emergencies

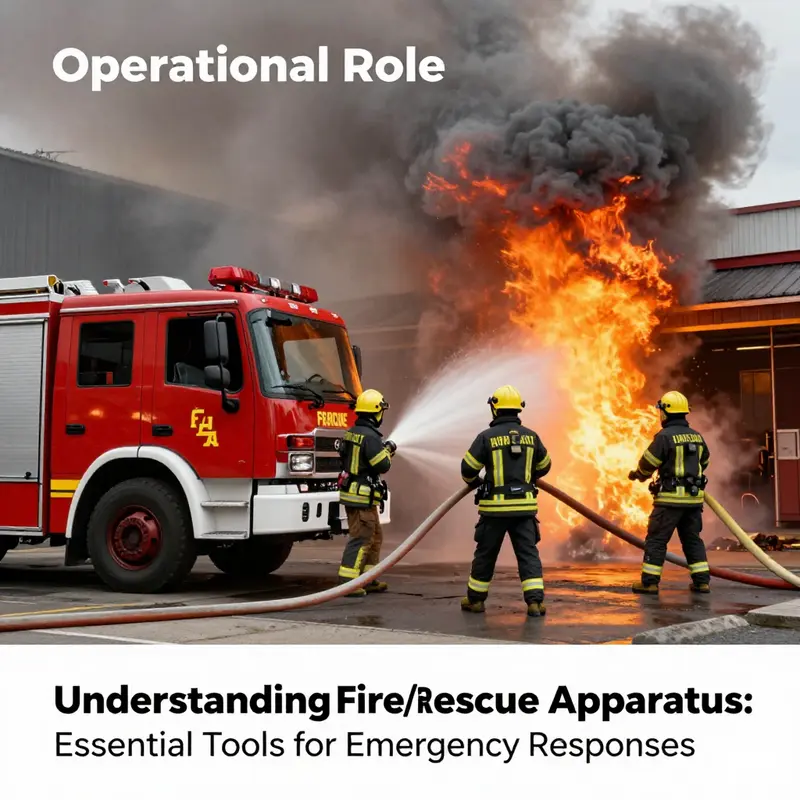

Across the urban grid and into winding rural corridors, the fire/rescue apparatus arrives as more than a machine. It is a moving, thinking extension of the responders whose lives depend on rapid, coordinated action. The vehicle’s exterior is a shield and platform, but its true power lies in what it carries inside: water and foam for suppression, rescue tools for extraction, protective gear for responders, lighting and comms to guide decisions, and the ability to adapt to a chaos that shifts in moments. This is where training translates into action. The apparatus anchors a sequence that begins the instant sirens slice through noise and smoke and ends only when the last patient is stabilized, the scene is made safe, and operators can depart with a clear, documented outcome. In emergencies, the apparatus and its crew move as a single system, each part synchronized to achieve more than any one element could on its own.

The operational tempo of an incident scene hinges on the vehicle’s capacity to perform multiple, interwoven tasks without pause. First, rapid response is essential. The apparatus is designed to arrive quickly, with systems primed for immediate action. On arrival, the pump or pump-and-pipe capabilities that deliver high-pressure water into the heart of a structure fire become the first line of defense against it. Simultaneously, other components are readied for deployment: hoses are laid out to douse or redirect flame paths, while foam or other extinguishing agents can be introduced where water alone would be insufficient. In many fires, the water supply must be sourced from hydrants, hydrant connections, or even inland water sources, requiring a flexible pump system and a meticulous understanding of the surrounding infrastructure. This ability to adapt water supply under pressure is one of the critical differences between a good response and an effective one.

Structure fires also reveal the dual purpose of the apparatus as a means of access. Ladder or aerial capabilities extend up to upper floors, enabling not only firefighting access but also rescue operations. The higher you reach, the more complex the risk landscape becomes: stairs are smoke-choked, doors may be trapped by heat and collapse, and victims can be found in rooms that shift from safe to dangerous in seconds. The apparatus, therefore, serves as both a tool and a gateway—an instrument of access that must be precise enough to support safe entry and sound enough to sustain a coordinated retreat if conditions deteriorate. In this sense, the apparatus is a temporary fortress that enables responders to control lines, manage air supply, and maintain visibility through dense, shifting environments.

In parallel with suppression, the rescue function sits at the core of every mission. The hydraulic rescue tools that responders deploy to extricate victims from twisted metal or trapped occupants in a vehicle or collapsed structure are the epitome of a careful, forceful balance. These tools cut, spread, lift, and separate in ways that demand not only mechanical capability but also situational empathy—understanding what maneuver will minimize further harm while preserving the possibility of life-saving intervention. The rescue phase often requires a steady hand, a calm mind, and a willingness to adjust tactics in response to evolving conditions. The presence of a capable rescue ensemble within the apparatus underscores the truth that firefighting is not only about fighting flames but about rescuing people from peril with the least amount of additional risk.

Medical emergencies add another layer of complexity. Ambulances parked in close reach of the scene bring advanced life support capabilities to the transport phase, ensuring that critical care continues during movement toward a hospital. The handoff from on-scene care to in-transit care becomes a seamless continuum when the apparatus functions as a hub of EMS assets. In many urban responses, this continuum is as important as the suppression work itself; the patient’s vitals, the stability of airway management, and the timely administration of life-saving interventions can determine outcomes that extend far beyond the scene. The apparatus, then, must be ready to support these medical requirements with power supply, lighting, and space for care teams to operate without disruption.

Beyond the immediate needs of a fire or accident, the apparatus serves as a mobile command post that enables incident leadership to coordinate a broad constellation of resources. A large, chaotic incident—whether it involves structure fires, multi-vehicle collisions, or hazardous material exposure—demands clear, centralized decision-making. The vehicle’s internal space becomes a planning room where incident commanders assess risk, allocate personnel, and adjust tactics as new data arrives. Communication systems are not merely conveniences; they are lifelines that connect responding units, hospitals, public safety agencies, and support teams. When the scene swells with responders, the apparatus must maintain situational awareness, track water usage and asset deployment, and preserve a reliable chain of command. In this context, a well-designed unit becomes a moving nerve center, translating field observations into strategic responses that protect life and property.

Technological capabilities embedded in modern fire/rescue apparatus also broaden the scope of what responders can achieve. A high-capacity water and foam system can address a spectrum of fire types, from hydrocarbon fuels to structural timber, allowing responders to select the most effective agent for the moment. Long-range monitors and versatile discharge points extend reach, enabling teams to address flames from a safe distance or to concentrate water in critical zones while limiting exposure to heat and smoke. Efficiency in water management—such as rapid diversion to protect exposures or to reduce a fuel source’s persistence—can shorten a fire’s growth phase and improve the chances of safe evacuation. The pump, not simply the line, becomes a partner in the fight, coordinating with the nozzle team, the foam pros, and the rescue crew to shape a dynamic, responsive operation.

The specialized rescue units that accompany many missions illustrate another facet of the apparatus’s operational breadth. In building rescues, for example, developers have explored systems that provide vertical access, such as belt-based ascent mechanisms with standing steps that travel along a tower. While the specifics vary by jurisdiction and equipment philosophy, the underlying principle is consistent: extend the reach of the responders beyond conventional stairs and ladders, enabling safer, more controlled ascent and descent for occupants and rescuers alike. These systems remind us that the apparatus is not a single function but a constellation of capabilities that can be adapted to the geometry of a scene—whether it is a high-rise, a structurally compromised facility, or an area where access is otherwise difficult.

The relevance of standards and training cannot be overstated. The NFPA and other safety bodies provide the blueprints that guide equipment design, maintenance, and operation. These guidelines ensure that what involves a rapid downshift from high-pressure water to delicate, life-preserving procedures remains predictable and auditable under stress. For responders, this translates into confidence: when a hose line is pulled with a certain pressure, when a rescue tool is activated, or when a command post sets a perimeter, the behavior of the system is governed by shared rules and tested protocols. The stability of these systems rests on continuous training, rigorous inspection, and a culture that values patient life as the central mission. In the larger arc of a responder’s career, ongoing education—such as specialized certificates and courses that formalize readiness for diverse scenarios—frames a professional path that aligns with real-world requirements. For those exploring how such credentials shape a career, see the discussion on unlocking your future: the vital role of fire safety certificates in your career journey.

In practice, the chain of events at an incident is not a sequence of independent actions but a choreography of interdependent moves. The apparatus delivers water, ushers people to safety, provides access where walls and roofs impede entry, and keeps the scene under control through communications, lighting, and decision-support. It is a tool for resilience, designed to endure long hours of arduous work under extreme conditions and to return ready for the next call. This resilience is not incidental; it is embedded in design choices—how the chassis behaves on uneven surfaces, how the pump responds to sudden shifts in demand, how the crew can access the interior while maintaining essential life support systems. The result is a system that holds the line against heat, smoke, and collapse while opening doors to possibility and hope.

As the incident winds down, the apparatus hands off to investigators, investigators, and public health or environmental teams, while responders begin the careful process of overhaul, salvage, and debrief. The transition from active suppression to recovery hinges on the same principle that governs every other moment of the operation: clear, deliberate action that prioritizes safety, accuracy, and accountability. In this sense, the real measure of an apparatus’s effectiveness is not merely its capacity to generate a plume of water or to cut through wreckage, but its ability to preserve life, minimize harm, and restore order with dignity and speed. The chapter in the broader article about the vehicle’s role in emergencies thus closes not with a final verdict on gadgets but with a recognition of how a well-built, well-led response system converts trained human skill into tangible safety and lasting community protection.

For readers seeking a deeper appreciation of the standards that govern this work and the professional pathways that sustain it, authoritative resources are available from the NFPA. https://www.nfpa.org/

Breath, Barrier, and Bond: PPE as the Critical Interface of Fire/Rescue Apparatus Performance

PPE is more than clothing or equipment; it is the human-vehicle interface that defines what a responder can endure, see, and accomplish inside the unfamiliar and unforgiving environments that fire and rescue operations routinely present. In the harsh calculus of firefighting and emergency rescue, PPE forms the last, most immediate line of defense against radiant heat, toxic smoke, hazardous chemicals, and random debris that can shape a scene in an instant. The apparatus itself provides the platform—water, foam, hydraulics, lights, radios, and access—but PPE translates that platform into a survivable, controllable mission. The synergy between person and machine is not accidental; it is a carefully engineered relationship built on protective performance, cognitive clarity, and physical feasibility. When responders step onto the fireground, the PPE they wear determines how long they can stay, what they can do, and how safely they can retreat under pressure. It is the quiet, relentless negotiator between urgency and safety, guiding decisions from first entry through rescue, overhaul, and recovery.

At the core of firefighting PPE is a turnout system designed to withstand both radiant and convective heat. A jacket and pants set forms a thermal barrier while permitting enough mobility for ladder work, weaponized debris removal, and victim handling. But this barrier is more than a single layer; it is a multicomponent system that works in concert with the helmet, the hood, the gloves, and the boots. Each item has a specialized role. The helmet protects the skull from falling objects and radiant heat; the face shield reduces glare and protects the eyes while maintaining visibility through smoke and heat haze. The hood minimizes heat seepage at the neck and shoulders, a critical junction where heat can funnel toward the torso. The gloves must balance dexterity and protection; the boots must provide traction on slick surfaces while resisting high temperatures and sharp objects. These elements are not chosen in isolation; they are selected as a compatible ensemble that maintains tactile feedback for delicate tasks, such as lifting a trapped victim or handling a charged hose without compromising grip or grip safety under stress.

Underneath the outer shell sits the Self-Contained Breathing Apparatus, or SCBA, a lifeline for safety that defines air quality, cognitive function, and duration on scene. The SCBA is not merely a supply of air; it is a shield against inhalation of toxic gases and fine particulates that accumulate quickly in enclosed spaces. A good SCBA maintains a stable positive pressure, but it also adds weight and heat near the chest and back, influencing posture and fatigue. The balance between protection and burden is a recurring theme in PPE design and use. Similarly, integrated communication devices, eye protection, and thermal imaging capabilities may be specified as part of a responder’s PPE kit, ensuring that teams can coordinate effectively even when visibility is compromised. The impact of these components on decision-making cannot be overstated. When heat exposure rises or smoke reduces visibility, a firefighter’s ability to hear, see, and communicate shapes the tempo of action—forcing rapid risk assessment, task prioritization, and, when necessary, a strategic retreat to a safer location.

The importance of PPE extends beyond the hardware of garments and gas masks. It is an entire system of protection, maintenance, inspection, and training that culminates in safer decisions and longer, more effective engagement on the fireground. A 2022 report reinforces this view by noting that firefighters should be equipped with at least 11 core pieces of basic protective equipment to perform duties safely. This figure serves as a practical benchmark for agencies seeking to standardize protection while acknowledging the realities of wear, tear, and resource constraints. The list of core items underscores the breadth of protection required: durable shells that resist heat, robust respiratory protection, head and foot protection, hand protection, and a reliable means of communication and situational awareness. But numbers alone do not guarantee safety. The real value lies in how well these pieces fit together, how consistently they are maintained, and how readily responders can inspect and replace worn components before they fail in the heat of a crisis.

Effectiveness of PPE is not solely physical; it also shapes cognition. The protective system must not impede a responder’s ability to think clearly under pressure. Excessive insulation or poorly balanced weighting can accelerate fatigue, hamper mobility, or dull sensory perception—each of which raises the risk of misjudgments in dynamic scenes. Consequently, PPE design strives for a careful equilibrium: high heat resistance and chemical protection without unduly restricting movement or endurance. This balance requires ongoing attention to materials science, ergonomics, and user feedback from the field. The cognitive load of donning, doffing, and adjusting PPE in hazardous environments demands consistent training and discipline. When responders are grounded in practiced routines for donning and checking PPE, they gain confidence and preserve mental resources for strategic tasks, such as ladder placement, victim extraction, or the management of water supply and hose lines.

Standards and regulation provide the framework that ensures PPE meets predictable performance criteria. In many places, national standards establish minimum requirements for protective quality, fit, and maintenance. They specify how often PPE should be inspected, how parts should be replaced, and what constitutes acceptable wear. In one national context, for instance, mandatory standards articulate guidelines for industries such as firefighting, including replacement schedules and inspection protocols. This regulatory backbone helps unify practices across departments and regions, ensuring that a firefighter’s PPE remains responsive to evolving hazards and new technological insights. Beyond national norms, internationally recognized standards bodies and leading safety organizations continually refine criteria to address emerging risks, materials, and designs. The result is a layered system of compliance, with annual checks, periodic fit-testing, and continuous education reinforcing the link between PPE and operational readiness. Many agencies also align their PPE programs with trusted resources such as the National Fire Protection Association (NFPA), whose standards guide best practices for equipment selection, testing, and upkeep.

PPE does not exist in a vacuum; it must be compatible with the fire/rescue apparatus and its operating environment. The design and configuration of a response vehicle influence how PPE is deployed and stored, how quickly layers can be donned, and how air supply management is coordinated during a long or complex incident. For instance, the workflow at a rescue scene—whether it involves a vehicle crash, a building collapse, or a hazardous-material incident—demands rapid access to PPE, reliable decontamination procedures, and streamlined replenishment cycles. A well-sequenced PPE program supports these workflows by ensuring gear is organized for quick access, filters and cartridges are within their service life, and protective layers do not interfere with a responder’s ability to operate pumps, monitors, and rescue tools. The priority remains clear: PPE should empower responders to proceed with confidence, maintain situational awareness, and preserve heat stress limits while performing critical tasks. When PPE is well integrated with the apparatus and incident command is effective, teams can advance through phases of operation with a steadier hand and a steadier heart.

As the professional landscape evolves, so too does the emphasis on training and certification around PPE. Ongoing education helps responders interpret evolving hazard profiles and adapt to new materials and protective technologies. Programs that emphasize PPE inspection, donning and doffing protocols, decontamination, and proper storage reinforce a culture of safety rather than mere compliance. For individuals seeking practical guidance on how PPE intersects with daily readiness, resources such as fire safety essentials certification training offer accessible frameworks for building and maintaining protective competency. This kind of program foregrounds the practicalities of PPE use, from ensuring proper fit to recognizing signs of wear and tear, and it helps bridge the gap between theory and field performance. You can learn more through the dedicated resources linked here: fire safety essentials certification training.

The research literature reinforces the protective value of PPE beyond immediate physical safety. A 2024 study highlights PPE’s effectiveness in reducing firefighter exposure to a range of hazardous chemicals, which has implications for long-term health and fitness for duty. The findings emphasize that PPE not only shields the lungs and skin but also plays a decisive role in limiting cumulative occupational exposure to combustion byproducts. This broader health context matters because the risks of chemical exposure accumulate over repeated firefighting deployments. PPE performance, maintenance, and proper use thus contribute to both acute safety and long-term well-being, underscoring why investments in protective gear, training, and regulatory compliance pay dividends across a responder’s career.

In sum, PPE is the indispensable link between a fire/rescue apparatus’s capabilities and the human beings who must operate within its reach. It translates the apparatus’s power into survivable action, preserves cognitive function under stress, and enables precise, decisive operation in the most demanding environments. When PPE is designed, inspected, and used as an integrated system—aligned with standards, reinforced by training, and supported by a culture of safety—the result is a responder who can reliably harness the full potential of the apparatus while protecting the health and lives of both crew and civilians. The conversation around PPE, therefore, is not a peripheral concern but a core driver of mission success on every fireground. As crews face increasingly complex hazards, the emphasis on protective gear—and the systems that sustain it—will continue to shape how fire/rescue apparatus is deployed, how incidents are managed, and how communities stay safe in the face of danger.

Further reading and context can be found through external research that broadens understanding of PPE’s protective capabilities and exposure mitigation. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC11396578/.

In the Line of Compliance: How Environmental and Safety Regulations Shape Fire/Rescue Apparatus Design

A fire/rescue apparatus is more than a collection of hoses, pumps, and ladders; it is a mobile system that must perform under extreme conditions while meeting a web of environmental and safety obligations. The drive to save lives and protect property sits beside a parallel mandate to minimize ecological disruption, safeguard responders, and comply with a shifting landscape of rules. Designers, manufacturers, and departments operate within this complex sphere, where every structural detail, every choice of propulsion, and every operational feature is weighed against standards that aspire to be as dynamic as the hazards these vehicles confront. The result is a machine that must be ready to answer the call with speed and reliability, yet do so within a framework that emphasizes responsibility to people, communities, and the environment. It is this convergence of mission, regulation, and practicality that shapes the essence of modern fire/rescue apparatus design.

Emissions standards are perhaps the most visible regulatory influence on today’s apparatus. In many regions, engine selection is constrained or guided by environmental limits that track fuel-economy progress, air-quality goals, and the broader push toward cleaner mobility. The regulatory conversation often centers on tiers or phases that define permissible emissions from vehicle powertrains. In practice, this means that the core propulsion system—its efficiency, exhaust treatment, and aftertreatment architecture—must be selected and integrated with an eye toward long-term viability. Departments increasingly weigh alternative-fuel technologies and hybrid approaches as a way to reduce particulate matter, nitrogen oxides, and greenhouse gas footprints without compromising the ability to deliver water, foam, or other suppression agents when minutes matter. These decisions ripple outward, affecting not only initial vehicle cost but maintenance planning, fuel logistics, and the availability of technicians capable of servicing more sophisticated powertrains. In parallel, manufacturers must ensure that on-board diagnostics and emissions-control systems withstand the rough conditions of daily use—from dusty siting to cold starts at rural depots—without compromising reliability.

Noise regulations add another layer of consideration, especially in dense urban environments or near schools, hospitals, and other sensitive zones. A fire/rescue apparatus must balance the demand for rapid, high-output pump operations with the moral and legal obligation to limit nuisance and disturbance. Noise limits drive design choices for engine management, pump engagement, exhaust routing, and noise-dissipating enclosures. Engineers explore ways to throttle or smooth the noise profile during critical tasks such as initial knockdown, while preserving the ability to deploy long-range monitors and reach flames where visibility is poor. The challenge is to deliver the required performance—flow rates, reach, and maneuverability—without creating avoidable acoustic stress for nearby residents or responders operating in close quarters. The result is a system that can adapt its acoustic footprint to the context, using insulation, vibration damping, and intelligent control algorithms to keep sound levels within acceptable bounds while maintaining effective suppression and rescue capabilities.

Fluid handling and waste disposal regulations touch the heart of the apparatus’s day-to-day operations. Hydraulic fluids, foams, and other extinguishing agents must be managed in a way that prevents environmental contamination during both use and maintenance. This regulatory frame encourages secondary containment strategies, careful routing of fluids through sealed systems, and robust procedures for leak detection and spill cleanup. It also shapes how departments design fueling and refueling procedures, waste collection, and the on-board storage of contaminated materials. The result is a safer operating envelope for firefighters and a minimized risk of soil or waterway contamination in the event of a spill or equipment failure. Across maintenance cycles, environmental compliance fosters disciplined handling of hazardous wastes, proper disposal of worn-out components, and documentation that demonstrates adherence to regulatory expectations and stewardship commitments.

Central to the regulatory conversation is safety standards that govern the structure, equipment, and operation of the vehicle itself. A cornerstone in this realm is the set of guidelines and codes that specify vehicle strength, visibility, lighting, braking, and protective equipment—for occupants and the public alike. These standards influence how the chassis is integrated with bodywork, how cab and crew compartments protect responders during crashes, and how systems such as emergency lighting and audible signals are calibrated for maximum effectiveness without compromising safety or compliance. Moreover, occupant safety standards drive the placement of seats, harnesses, escape routes, and protective gear. They push designers to incorporate redundant protections and to validate that day-to-day operations—driving to the scene, deploying tools, engaging pumps, and rescuing victims—do not expose firefighters to preventable risk.

The NFPA 1917 standard, in particular, is a touchstone for automotive fire apparatus. It provides a comprehensive framework for vehicle structure, visibility, lighting, braking, and the protective equipment firefighters rely on when responding to emergencies. Compliance with NFPA 1917 is not a one-off check but a sustained process of design evaluation, testing, and refinement. Standards bodies continually revise these codes to reflect advances in technology, lessons learned from field operations, and evolving safety expectations. For manufacturers, this means a moving target that requires robust validation protocols, rigorous quality control, and a willingness to update designs in response to new criteria. For fire departments, it means ongoing training, inspections, and certification efforts to ensure that equipment not only meets a baseline of safety but remains dependable in the face of aging fleets and changing operating environments. The interplay between regulation and practice thus reinforces a culture of continuous improvement, where lessons from the field feed back into safer, more capable apparatus.

In practical terms, regulatory influence extends beyond the engine and the cab into every subsystem that touches the mission. Pumps, tanks, and water/foam delivery systems must be designed for reliability under adverse conditions, including heat, vibration, and rough terrain. This imposes constraints on materials, connections, and serviceability. A design that looks excellent on paper may falter in the field if it cannot be easily inspected, repaired, or drained of hazardous residues after use. Regulations encourage modularity and serviceability, enabling teams to replace worn components quickly and to perform routine maintenance without specialized facilities. The design ethos becomes one of resilience, where the apparatus can be restored to a ready state promptly, even as environmental laws require careful handling of fluids, waste, and emissions.

From a lifecycle perspective, regulatory demand also accelerates the adoption of digital tools and data-driven maintenance. Telemetry, emissions tracking, and fault-diagnostic capabilities provide the granular visibility needed to ensure ongoing compliance. When fleets are monitored in real time, departments can optimize routes, schedule preventive maintenance before failures occur, and document adherence to environmental and safety standards. This digital dimension aligns with broader trends in public safety toward smarter, more accountable operations, where every decision is traceable and auditable. As a result, the apparatus becomes not only a vehicle for emergency response but a node in a larger system of safety, environmental stewardship, and data-guided improvement.

The regulatory story is not uniform across all regions. Different jurisdictions weigh local air quality, noise, and waste handling in ways that affect procurement, maintenance, and even the availability of certain fuels. This reality asks departments and manufacturers to tailor solutions to local conditions while preserving core safety and performance standards. It also underscores the value of professional development and training, so responders and engineers alike stay current with changing rules and best practices. For those who seek practical pathways to align compliance with capability, ongoing education and certification are essential. The field benefits when responders understand not only how to operate effectively in a crisis but also why certain design choices are mandated by law, policy, and the aim of minimizing harm to the environment and to the communities served.

For those interested in the training side of compliance and how it supports safer equipment and operations, resources exist that emphasize the essentials of fire safety certification and hands-on readiness. Fire safety training materials and certifications help ensure that personnel can operate, inspect, and maintain apparatus in ways that uphold regulatory requirements while maximizing effectiveness on the fireground. Fire Safety Essentials Certification Training offers a practical bridge between theoretical standards and field readiness, underscoring how rigorous preparation translates into safer and more compliant practice in high-stakes environments.

As the standards landscape continues to evolve, the relationship between regulation and design remains dynamic. The goal is not to constrain ingenuity but to direct it toward solutions that protect people and the environment without sacrificing speed or reliability. The modern fire/rescue apparatus embodies this balance. It is a device engineered to be resilient in the face of harsh conditions, capable of delivering life-saving interventions while respecting the community’s exposure to emissions, noise, and hazardous materials. It is simultaneously a tool for rescue and a testament to responsible stewardship, a vehicle whose very existence demonstrates that efficiency, safety, and ecological accountability can coexist without compromise. The chapter on these environmental and safety regulations is, in essence, a chapter about the ethics of design: the recognition that every technical decision carries social consequences and that the best apparatus emerges from thoughtful negotiation among mission imperatives, environmental duty, and the evolving expectations of the public we serve.

For those seeking further authoritative guidance, NFPA 1917 remains a central reference, offering detailed requirements and ongoing updates that influence every facet of apparatus development and verification.

External resource: https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-all-codes-and-standards/nfpa-1917

Final thoughts

Fire/rescue apparatus are indispensable assets in emergency response, integrating advanced technology and well-designed components to enhance operational effectiveness. The critical role they play, alongside the importance of Personal Protective Equipment (PPE), ensures the safety of both responders and the communities they serve. By adhering to environmental and safety regulations, these apparatus not only fulfill their functional purposes but also become pivotal in safeguarding lives during emergencies.