In emergency situations, particularly vehicle extrications, the use of hydraulic tools such as hydraulic rams has become indispensable. As vehicle accidents increasingly prompt swift evacuations, understanding the dynamics of these tools provides critical insights for individual car buyers, auto dealerships, and small business fleet buyers. This article delves deep into the concept of RAM Fire Rescue, emphasizing the integration of hydraulic rams within firefighting and rescue operations. Each chapter will elucidate distinct aspects of hydraulic rams—from their operational utility and safety protocols to their comparative advantages over other tools and future technological trends. Through this exploration, stakeholders can appreciate the significance of hydraulic rams in ensuring safety and efficiency in rescue scenarios.

The Pushing Force: Hydraulic Rams at the Heart of Ram Fire Rescue

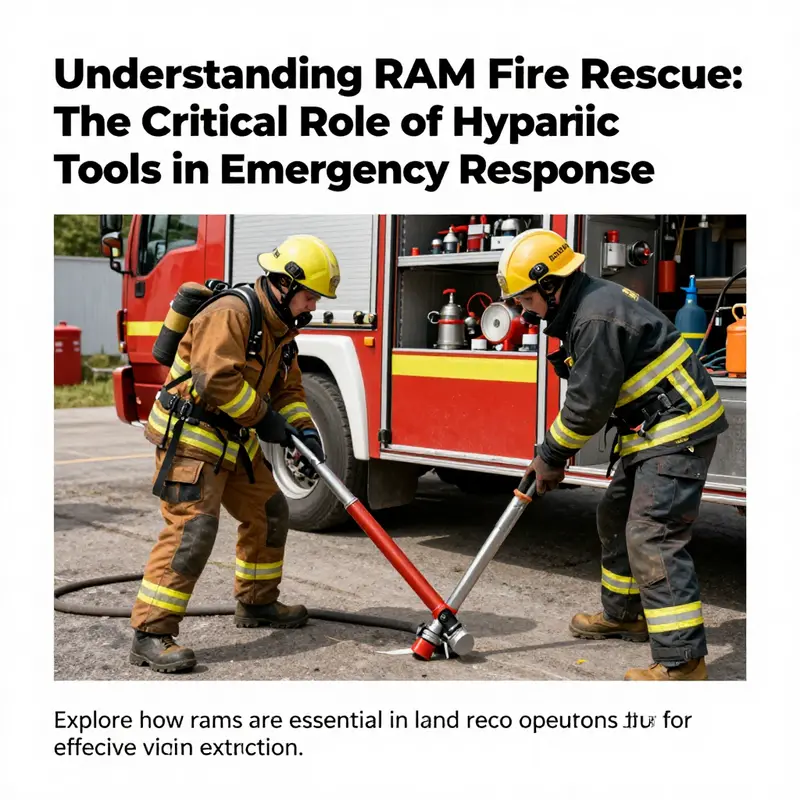

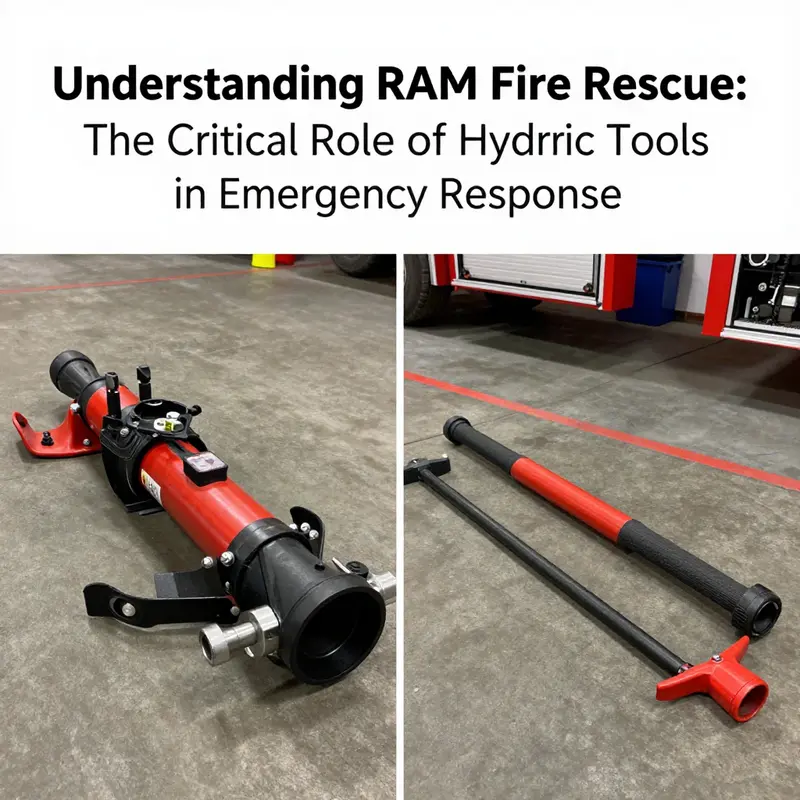

When a crash strands a driver inside a crushed chassis, every second counts and every tool must earn its place in a tight geometry of metal and risk. Among the core instruments that responders rely on, hydraulic rams stand out for their ability to generate controlled pushing force in confined spaces. They are not improvised pry bars; they are purpose-built devices that extend a piston and move heavy components apart with precision. In the spectrum of ram fire rescue, these tools translate energy into space, creating a corridor of safety for rescuers to reach the trapped patient, assess injuries, and begin careful extraction. The image is simple in its physics, yet sophisticated in practice: a robust hydraulic system converts liquid pressure into linear displacement, delivering a pushing action that can reconfigure a vehicle frame, separate a door frame from a dashboard, or lift a crushed pillar enough to introduce a stabilization point. What makes hydraulic rams indispensable is not just raw force, but the ability to apply that force incrementally and predictably. In the stress of a live operation, responders must balance speed with control, motion with restraint, and risk with possibility. The ram provides a trusted method to increase space without compromising the remaining structural integrity of the vehicle or the comfort of a patient who still cannot bend or move unaided. The operator must read the resistance of the metal, feel the cadence of the ram’s extension, and anticipate how the metal will respond to each millimeter of travel. It is a dance of feedback, where force curves and material behavior guide every move. The goal is not to tear or twist structures beyond repair but to unlock a path that permits careful, staged extraction. In practice, that means identifying a stable anchor point for the ram and planning a sequence that respects both the patient’s condition and the safety of responders. Hydraulic rams differ from other pushing tools in a crucial way: they extend rather than pry. Where a spreader or cutter might force an opening by prying, a ram pushes from within, pressing apart sections of metal where space is scarce. This makes rams particularly effective in deep-crush scenarios where room to maneuver is limited and the risk of a swing or sudden collapse is real. A typical ram offers force ranges that can range from twenty to forty tons, a scale that sounds abstract until you witness the wedge of metal move just enough to reveal a leg or an airbag, or to relieve pressure from a chest or neck. The emphasis is on controlled, incremental displacement. Each movement must be verifiable, repeatable, and compatible with the patient’s airway, breathing, and circulation constraints. The operator’s sense of timing matters as much as the machine’s pressure gauge. In many operations, rams function in harmony with other hydraulic tools. A ram may work in concert with a cutter to free limbs, with a spreader to widen a doorway, or with stabilizing devices to prevent shifting soil and glass from compounding hazards. This collaboration is essential because real-world extrications do not unfold in neat lines. They unfold in a cluttered, sometimes uneven space where debris and vehicle fatigue alter the way force travels through metal. The ram’s strength is amplified when it has a solid anchor. Fire rescue teams learn early that a ram cannot perform solo work in an unstable environment. Chains, struts, cribbing, and anchor points must be established to hold the vehicle in place while the ram applies its push. Without those anchors, the same force could trigger an unpredictable shift that endangers the patient and the rescuers. Stability is the silent partner of power. The hydraulic system itself demands respect. Its fluid, hoses, seals, and pumps require sustained maintenance to prevent leaks, heat buildup, or sudden failures that could compromise a critical moment. Regular checks of oil quality, pressure settings, and hose integrity become routine in training and in field readiness. Even the best ram cannot compensate for worn components or degraded seals; thus, the equipment’s reliability rests on meticulous upkeep and a culture of proactive inspection. Beyond the mechanics lies a human dimension. Operators must understand the patient’s condition and the scene’s dynamics. They must communicate with teammates who are coordinating a complex choreography of tools and tasks. The ram’s operation is rarely a solitary act; it demands situational awareness, precise hand signals, and a shared mental model of how each movement alters the space around the patient. In this sense, hydraulic rams contribute to a larger philosophy of restraint and respect for life. They empower responders to create opportunity rather than to force an exit. The most effective teams blend technical skill with careful patient handling. Training plays a central role here. A well-prepared crew rehearses not only the mechanics of extending and retracting the ram but also the decision-making about when to push, how far to push, and how to sequence other tools to avoid overburdening the patient or causing secondary injuries. This is why ongoing education matters. It is also why accessible resources about safety and certification are essential for frontline responders seeking to deepen their competence. For those pursuing professional development, practical courses that emphasize core rescue competencies—combining hydraulic tool operation with patient care, scene safety, and teamwork—are invaluable. See how modern responders approach this through dedicated training programs such as Fire Safety Essentials Certification Training, which emphasizes foundational safety, tool ethics, and scenario-based practice Fire Safety Essentials Certification Training. The goal is not only to master the mechanical sequence of a RAM-style tool but to embed it within a humane, patient-centered rescue process. As with any technical skill in rescue work, the boundaries of what is possible are tested by the environment and the person trapped inside. A ram is a force multiplier, expanding the range of what responders can achieve when time, space, and care converge. It is the team’s job to ensure that the force applied is neither excessive nor aimless, but deliberate, measured, and guided by the patient’s condition and the scene’s constraints. The broader context of ram fire rescue is anchored in standards and best practices that help responders align their methods with what has been proven to work in the field. Official guidance on equipment and standards informs decisions about which tools to select, how to maintain them, and how to operate within safety margins. The material here reflects a convergence of engineering, field experience, and ongoing professional development that keeps fire rescue teams effective in demanding situations. For responders, the practical takeaway is simple: hydraulic rams extend safe space, stabilize work zones, and enable careful extraction when used with discipline and coordination. They are a core element of a toolbox that keeps patients alive while preserving the integrity of the vehicle and the rescuers who carry the responsibility of care. The result is not just a removal but a carefully choreographed process where force is applied with purpose, and every action is measured against the patient’s best interests. In this sense, the term ram fire rescue evokes more than a device. It conjures a method—a disciplined approach to turning compressed time and twisted metal into a safer passage to the outside world. Those who study and practice it will tell you that the right tool, used properly, can be the difference between a difficult extraction and a life-saving one. For readers seeking deeper standards and official guidance, the Rescue Equipment Standard 2026 from the National Fire Protection Association provides comprehensive criteria to help shape tool selection and maintenance: https://www.nfpa.org/Code-Development/All-Codes-and-Standards/Document-List/805/Rescue-Equipment-Standard-2026

null

null

Rams Under Pressure: Safe Mastery of Hydraulic Rescue Tools in Fire and Rescue Missions

Hydraulic rams, often paired with other tools in the rescue ensemble, perform a precise and demanding role in fire and rescue work. They are not mere gadgets but integral instruments that extend the rescuer’s reach into environments where every second and every millimeter counts. The term ram fire rescue commonly conjures images of dramatic vehicle extrications, where crushed metal and tangled passengers test the limits of human restraint and mechanical leverage. In reality, the tool’s value rests on disciplined procedure, meticulous assessment, and the steady hands of trained teams. To understand how hydraulic rams function within a broader fire rescue operation is to see how modern emergency response blends physics with strategy, and how safety becomes a shared practice rather than a sequence of isolated actions. The chapter that follows situates the ram not as a single hero tool, but as a responsibly managed system whose success hinges on preparation, teamwork, and unwavering vigilance about risks that may emerge as the scene evolves.

Before any physical act of prying, spreading, or expanding is attempted, the rescue operation begins with careful assessment and preparation. The scene must be read like a map, with danger zones identified and controlled. Leaking fuels, flammable liquids, or rapidly shifting loads demand immediate mitigation. High-pressure gas cylinders and live electrical lines require isolation or de-energization when possible. The aim is not to rush but to reduce unknowns. Stabilization demands a plan that accounts for vehicle dynamics, structural integrity, and the potential for secondary collapse. Even a seemingly minor misstep, such as forcing a section of the frame without regard to how the component will respond under load, can convert a contained hazard into a life-threatening momentum. The safest path, therefore, begins with a clear risk picture and a decision that the minimum necessary force will achieve the desired space for extraction.

With assessment complete, rescuers turn to establishing a stable anchor point. The ram’s power arises from the hydraulic system’s ability to convert pressure into linear force. This force acts through the ram’s ram head and operates most effectively when a robust anchor point is available to counteract the tool’s reaction. That counterforce is not a mere afterthought; it is the linchpin of safe operation. Vehicle structural members, such as the chassis rails or designated primary anchoring points, are preferred. To prevent damage to critical load paths or to the rescue equipment itself, many teams employ dedicated anchor plates or pads to distribute pressure. The goal is to avoid concentrating stress in a single spot, which could cause an unintended material failure or weaponize a misalignment. The anchor acts as a fulcrum for controlled movement, allowing rescuers to create the necessary space for patient access while keeping the surrounding structure as stable as possible.

Once anchors are in place, the team proceeds with deliberate, measured use of the tool. The ram is designed to push, pull, or spread, depending on configuration and tool class. However, the operator does not unleash maximum force at once. Instead, power is applied gradually, observing the structure’s response and listening for unusual sounds or shifts in alignment. Overloading the tool or misdirecting the ram’s thrust can bend metal unpredictably, trap a limb, or compromise the scene’s safety. Training emphasizes adherence to the device’s rated working pressure, often expressed in PSI, and the importance of incremental increases in force. In practice, operators maintain continuous situational awareness and maintain flexibility to pause if new hazards surface. This is not merely a technical caution; it is a moral imperative in a high-stakes environment where a single misstep can have cascading consequences for both victim and responder.

Equally central to safe ram operation is the use of appropriate personal protective equipment. Rescue work exposes personnel to high-velocity debris, sharp edges, hot surfaces, and the possible release of stored energy as metal yields under pressure. Fire-resistant clothing, helmets with face shields, cut-resistant gloves, eye protection, and sturdy footwear form the first line of defense. Respiratory protection may be necessary in smoke-filled or dust-filled environments. PPE is not a fashion statement; it is a barrier against injuries that can end a career or worse. The PPE requirements reinforce a broader mindset: operators must approach every movement with caution, ready to step back rather than push forward into uncertainty. This mindset helps maintain a calm tempo that supports precise action rather than reactive improvisation.

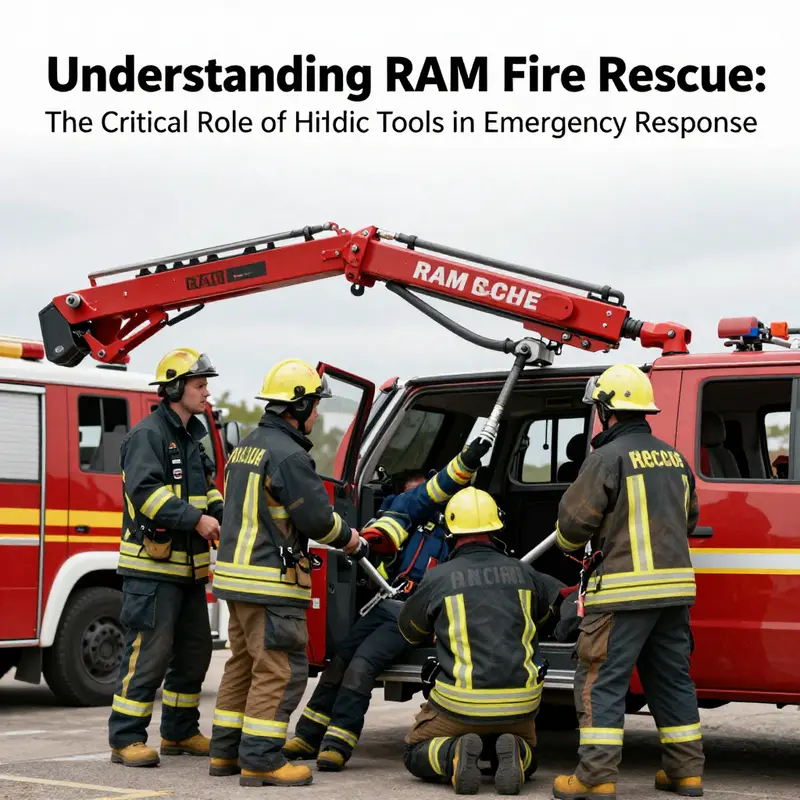

The social fabric of the rescue team is the ultimate force multiplier. Effective hydraulic ram work demands clear leadership and disciplined communication. An assigned incident commander or a designated group supervisor coordinates the overall plan, while operators report progress and hazards through a concise communication channel. As pressure is applied, team members must synchronize their actions—one person controlling the setup, another managing the ram, and others performing patient assessment or stabilizing tasks nearby. The emphasis on teamwork is not only about efficiency; it is about safety through redundancy. When a change in the scene occurs, the entire team must transfer awareness rapidly, readjusting roles and recalibrating the plan. A well-functioning team can anticipate failures before they happen and pivot to safer options without losing tempo in the rescue.

Environmental monitoring accompanies every stage of ram operation. Rescue scenes are dynamic, with fire progression, shifting loads, and new fuel sources creating evolving risk profiles. If smoke intensity increases, if the vehicle begins to shift, or if a structural member loosens, the team must halt operations and evacuate to a safer position. The restraint shown in stopping work is often the difference between a successful extrication and a new emergency. Environmental vigilance also means considering secondary hazards such as contaminated fuel, electrified frames, or the potential for a gas release. The on-scene judgment must always weigh the immediate extraction needs against longer-term safety for responders. In such a balance, the ram remains a tool in a greater repertoire whose use must be guided by the evolving realities of the scene.

Maintenance and inspection of hydraulic rescue tools cannot be an afterthought. The reliability of the ram hinges on systematic care of the hydraulic system, seals, hoses, and fittings. Regular maintenance—oil changes, leakage checks, hose wear assessment, and pressure tests—ensures the system remains ready for mission-critical tasks. A neglected tool is a ticking clock, ready to fail at the wrong moment. Teams that prioritize preventative maintenance reduce the likelihood of tool failure during a rescue and extend the life of equipment used to save lives. The mental model here is straightforward: dependability is earned through routine, not luck. Operators who treat maintenance as part of the mission guarantee that the ram will respond as expected when called upon.

To connect these practical principles with broader standards, it is useful to imagine the ram not in isolation but as part of a larger framework of equipment and training. The hydraulic ram’s effectiveness rises when it operates in concert with other tools, such as cutters, spreaders, and stabilization devices. The procedural choreography—the order in which tools are deployed, how space is created, and how victims are accessed—depends on the nature of the entrapment and the vehicle’s geometry. In this light, the ram becomes a precise instrument that fulfills a defined function within a well-rehearsed sequence. The value of this approach is clear in professional guidance that emphasizes equipment standards and safety in fire and rescue service operations. For readers seeking authoritative context on standards and guidance for this equipment, a reliable reference is the official guide on fire and rescue service equipment and standards.

The human element remains the backbone of successful ram operations. Training that emphasizes safety protocols, practical drill work, and scenario-based exercises builds the reflexes and judgment operators need. Those who pursue dedicated training, and who maintain a disciplined approach to safety, build a culture where the ram is a trusted tool rather than a risky improvisation. A practical path for ongoing education can be found in the resources outlining fire safety essentials and certification training, which reinforce core competencies and uplift the standard of care on real scenes. This integration of training, procedure, and equipment forms a resilient model that supports rescuers as they navigate the complex, high-pressure environments where ram fire rescue takes place. The emphasis is on ensuring every movement counts and every decision preserves life.

In sum, hydraulic rams are powerful yet highly disciplined tools within fire and rescue operations. Their success depends on thorough site assessment, solid anchoring, careful application of force, and continuous attention to safety. The teamwork that surrounds the tool—the communication, command structure, and shared situational awareness—transforms a potential hazard into a controlled rescue. Maintenance and readiness underwrite every successful extraction, ensuring that the ram performs when it matters most. As the field evolves, these principles remain central: respect for the tool’s capability, humility before the scene’s uncertainty, and unwavering commitment to safeguarding both victims and responders. The ram is not a solitary actor but part of a cohesive system designed to maximize safety, speed, and effectiveness on the toughest rescue moments. For readers who want to deepen their understanding of safety culture and training foundations in fire safety, consider exploring resources focused on essential certification and training for responders.

External resource: https://www.nfpa.org/codes-and-standards/fire-protection-engineering/technical-resources/for-fire-rescue-tools

Pushing for Space: The Vital Role of Hydraulic Rams in Vehicle Extrication and Fire Rescue

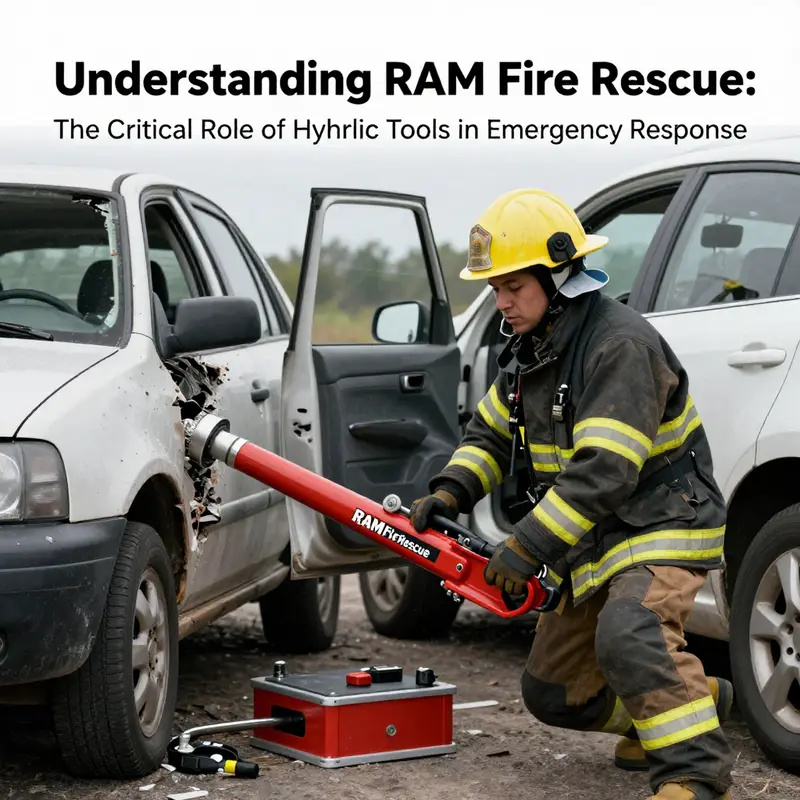

In the repertoire of tools that modern fire and rescue teams deploy, the hydraulic ram stands as a disciplined, purpose-built instrument. It is not a flashy contraption, but a workhorse that translates hydraulic pressure into a controlled, pushing force. In the common shorthand of the trade, the ram is part of the family of hydraulic rescue tools, but its job is distinct: to pry, push, and reposition heavy wreckage so that a trapped person can be freed without forcing a dangerous cut or undue movement of the victim. When people encounter the term ram fire rescue, it often conjures an image of brute force. In truth, careful technique and precise alignment are what separate a successful extrication from additional harm.

Vehicle extrication after a crash is a race against time and a test of geometry. The ram requires a solid anchor point—an intact floor pan, a sturdy door frame, or a reinforced pillar—against which to push. Once set, rescuers apply gradual, measured pressure to move the vehicle’s structure away from the trapped occupant. The aim is to create a pocket of space just large enough for a hand, a tool, or a torso, while maintaining stabilization of the vehicle to prevent shifts that could worsen injuries. The ram’s power comes from hydraulic fluid that transfers energy through pistons. With a few dozen tons of pushing force available, the operator can coax a crushed door jamb to hinge, or push a bent bumper away from a leg. The operator’s partner becomes the eyes and ears, guiding the ram to the most advantageous anchor and watching for any movement that could compromise the patient or the scene.

How does the ram compare to other hydraulic tools such as spreaders and cutters? The difference is simple in concept but profound in practice. Rams deliver pushing or spreading force from the inside outward. Spreaders open spaces by pulling or prying, often reaching into tight corners without an external anchor. Cutters, meanwhile, bisect metal to free limbs when space cannot be coaxed, or when glass and metal must be removed to reach the patient. In practice, crews rarely rely on a single tool. A deliberate sequence—stabilize, create space with the ram, then broaden access with spreaders or remove obstructing components with cutters—yields safer, faster extrication. A ram can set the stage by moving heavy metal away from the patient, reducing the risk of additional crushing during subsequent cutting or lifting.

There are clear advantages to a dedicated ram as a heavy-duty pushing device. Its durability matters when a frame is distorted and time is short. A ram’s design favors sustained force over a prolonged pull, which is essential when the objective is to reposition a displaced roof beam or to push back a collapsed seat frame enough to extract a torso without kinking a body. But rams have limitations. They require a reliable anchor point and a calculated push path. They are not versatile in reach compared to spreaders; their maximum effectiveness depends on where the anchor can be found and the angle of approach. If the anchor point slips or the operator misjudges the line of action, the resulting movement can create new hazards. That is why training, scene assessment, and a calm, controlled rhythm are as vital as the tool itself.

The place of the ram in fire rescue is not merely about brute force; it is about strategic force. Rescue teams practice precise load management, communicating constantly with the incident commander and with each other. They read the metal’s response to incremental pressure, looking for signs of yielding and listening for the telltale creak that warns of impending movement. In the broader context of equipment standards and safety guidelines, the ram is part of a family of tools whose reliability depends on regular inspection, maintenance, and correct setup. Standards documents from authoritative sources outline how tools should be inspected, when to retire components, and how to organize the hydraulic system for quick, clean operation in the heat of an emergency. Those guidelines help responders keep the pushing power available when it matters most. For readers seeking practical, day-to-day preparation, see the fire safety essentials certification training page. fire safety essentials certification training.

Those standards also remind us that the purpose of ram use is not to overpower a scene but to enable safer, faster access to a patient. A well-executed push can relieve the pressure of a trapped limb, widen the corridor through which a patient must pass, and reduce the time a patient spends under a load that could aggravate injuries. When integrated thoughtfully with other tools, the ram becomes part of a choreography rather than a single act of force. It requires careful planning to avoid creating secondary hazards, such as destabilizing a partially collapsed vehicle, shifting heavy components, or compromising a rescuer on the other side of a frame. In this sense, hydraulics in rescue work embody a core principle: power must be harnessed by precision, not by volume alone. The operator must anticipate outcomes, not just apply pressure, and continually reassess the scene as metal yields and space opens.

The broader takeaway is that ram technology is a critical enabler, but not a standalone solution. Its value grows when embedded in a well-structured rescue plan, a disciplined team, and a culture of continuous learning. Fire rescue, at its best, treats each tool as a means to shape the environment around an injured person, preserving life while minimizing harm. As standards evolve and training expands, the ram remains a steady reference point for what disciplined pushing can accomplish in the most demanding extrication scenarios. The narrative of ram fire rescue is thus a story of geometry, judgment, and teamwork—the quiet, methodical force that makes space for someone who cannot move on their own. For readers who want to connect theory with practice, the path from understanding the tool to applying it safely on scene often begins with informed training, meticulous preplanning, and a respect for the limits of any single device. This is how hydraulic rams stay not just powerful, but responsibly powerful, in the hands of those who must make quick, life-saving decisions under pressure.

External resource: https://www.gov.uk/government/publications/fire-and-rescue-service-equipment-and-standards

null

null

Final thoughts

The effective deployment of hydraulic rams in fire and rescue scenarios is vital for ensuring rapid and safe victim extrication. As this article highlights, understanding their operational roles, safety protocols, and the comparative benefits over alternative tools preserves the integrity of rescue missions. Additionally, staying abreast of emerging trends shapes the future of emergency response technology. By equipping teams with the right tools and knowledge, individual car buyers, auto dealerships, and fleet buyers can play an essential role in ensuring the safety and effectiveness of fire rescue operations.